Page 45 - MetalForming August 2011

P. 45

Drawing clearance

Gap

block Die

Blankholder

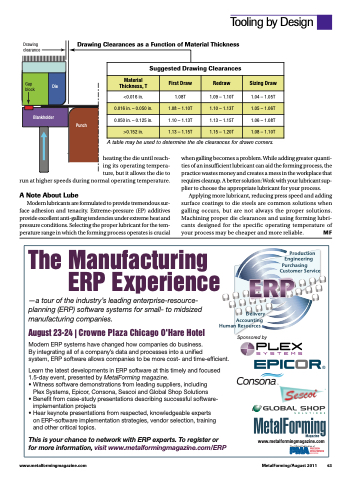

Drawing Clearances as a Function of Material Thickness

Punch

Material Thickness, T

<0.016 in. 0.016 in. – 0.050 in. 0.050 in. – 0.125 in.

>0.152 in.

First Draw

1.08T

1.08 – 1.10T

1.10 – 1.13T

1.13 – 1.15T

Redraw

1.09 – 1.10T 1.10 – 1.13T 1.13 – 1.15T

1.15 – 1.20T

Sizing Draw

1.04 – 1.05T 1.05 – 1.06T 1.06 – 1.08T

1.08 – 1.10T

run at higher speeds during normal operating temperature.

A Note About Lube

Modern lubricants are formulated to provide tremendous sur- face adhesion and tenacity. Extreme-pressure (EP) additives provide excellent anti-galling tendencies under extreme heat and pressure conditions. Selecting the proper lubricant for the tem- perature range in which the forming process operates is crucial

Suggested Drawing Clearances

A table may be used to determine the die clearances for drawn corners.

heating the die until reach- ing its operating tempera- ture, but it allows the die to

when galling becomes a problem. While adding greater quanti- ties of an insufficient lubricant can aid the forming process, the practice wastes money and creates a mess in the workplace that requires cleanup. A better solution: Work with your lubricant sup- plier to choose the appropriate lubricant for your process.

Applying more lubricant, reducing press speed and adding surface coatings to die steels are common solutions when galling occurs, but are not always the proper solutions. Machining proper die clearances and using forming lubri- cants designed for the specific operating temperature of your process may be cheaper and more reliable. MF

The Manufacturing ERP Experience

—a tour of the industry’s leading enterprise-resource- planning (ERP) software systems for small- to midsized manufacturing companies.

August 23-24 | Crowne Plaza Chicago O'Hare Hotel

Modern ERP systems have changed how companies do business.

By integrating all of a company’s data and processes into a unified

system, ERP software allows companies to be more cost- and time-efficient.

Learn the latest developments in ERP software at this timely and focused 1.5-day event, presented by MetalForming magazine.

• Witness software demonstrations from leading suppliers, including

Plex Systems, Epicor, Consona, Sescoi and Global Shop Solutions

• Benefit from case-study presentations describing successful software-

implementation projects

• Hear keynote presentations from respected, knowledgeable experts

on ERP-software implementation strategies, vendor selection, training and other critical topics.

This is your chance to network with ERP experts. To register or for more information, visit www.metalformingmagazine.com/ERP

Sponsored by

www.metalformingmagazine.com

MetalForming/August 2011 43

Tooling by Design

Production Engineering

Purchasing Customer Service

ERP

Delivery Accounting

Human Resources

ERP

ERP

ERP

www.metalformingmagazine.com

The Official Publication of