Page 23 - MetalForming December 2010

P. 23

70%

60

50

40

30

20

10

Conventional Steels

Generation 2

Mild

• Improved properties • Reduced cost

IF

BH

HS IF CMn

Generation 3

Current Area of Research

IS

HSLA

TRIP DP, CP

AHSS Grades

MART

TWIP SS

Austenitic-Based

Steels

forming. Instead of starting with a very strong MS steel, a common boron-based steel is heated to 850 C. At this temper- ature the strength of the steel is extreme- ly low and the steel is highly formable. The preheated blank is inserted into a chilled die, quickly formed, and then quenched as it remains in the die until the microstructure changes to marten- site. The benefits are the ability to form complex shapes; an extremely high strength martensitic final structure; and no problems with springback. The disad- vantage is a longer cycle time in the die.

Elongation

• Improved weldability

0

0 200 500 800 1100 1400 1700 ThecurrentAHSSareshowninFig.2

Tensile Strength (MPa)

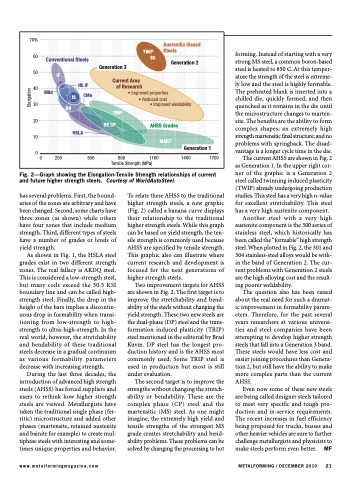

Fig. 2—Graph showing the Elongation-Tensile Strength relationships of current and future higher strength steels. Courtesy of WorldAutoSteel.

as Generation 1. In the upper right cor- ner of the graphic is a Generation 2 steel called twinning induced plasticity (TWIP) already undergoing production studies. This steel has a very high n-value for excellent stretchability. This steel has a very high austenite component.

Another steel with a very high austenite component is the 300 series of stainless steel, which historically has been called the “formable” high strength steel. When plotted in Fig. 2, the 301 and 304 stainless-steel alloys would be with- in the band of Generation 2. The cur- rent problems with Generation 2 steels are the high alloying cost and the result- ing poorer weldability.

The question also has been raised about the real need for such a dramat- ic improvement in formability param- eters. Therefore, for the past several years researchers at various universi- ties and steel companies have been attempting to develop higher strength steels that fall into a Generation 3 band. These steels would have less cost and easier joining procedures than Genera- tion 2, but still have the ability to make more complex parts than the current AHSS.

Even now some of these new steels are being called designer steels tailored to meet very specific and tough pro- duction and in-service requirements. The recent increases in fuel efficiency being proposed for trucks, busses and other heavier vehicles are sure to further challenge metallurgists and physicists to make steels perform even better. MF

has several problems. First, the bound- aries of the zones are arbitrary and have been changed. Second, some charts have three zones (as shown) while others have four zones that include medium strength. Third, different types of steels have a number of grades or levels of yield strength.

As shown in Fig. 1, the HSLA steel grades exist in two different strength zones. The real fallacy is AKDQ steel. This is considered a low-strength steel, but many coils exceed the 30.5 KSI boundary line and can be called high- strength steel. Finally, the drop in the height of the bars implies a discontin- uous drop in formability when transi- tioning from low-strength to high- strength to ultra-high-strength. In the real world, however, the stretchability and bendability of these traditional steels decrease in a gradual continuum as various formability parameters decrease with increasing strength.

During the last three decades, the introduction of advanced high strength steels (AHSS) has forced suppliers and users to rethink how higher strength steels are viewed. Metallurgists have taken the traditional single phase (fer- ritic) microstructure and added other phases (martensite, retained austenite and bainite for example) to create mul- tiphase steels with interesting and some- times unique properties and behavior.

To relate these AHSS to the traditional higher strength steels, a new graphic (Fig. 2) called a banana curve displays their relationship to the traditional higher strength steels. While this graph can be based on yield strength, the ten- sile strength is commonly used because AHSS are specified by tensile strength. This graphic also can illustrate where current research and development is focused for the next generations of higher strength steels.

Two improvement targets for AHSS are shown in Fig. 2. The first target is to improve the stretchability and bend- ability of the steels without changing the yield strength. These two new steels are the dual-phase (DP) steel and the trans- formation induced plasticity (TRIP) steel mentioned in the editorial by Brad Kuvin. DP steel has the longest pro- duction history and is the AHSS most commonly used. Some TRIP steel is used in production but most is still under evaluation.

The second target is to improve the strengths without changing the stretch- ability or bendability. These are the complex phase (CP) steel and the martensitic (MS) steel. As one might imagine, the extremely high yield and tensile strengths of the strongest MS grade creates stretchability and bend- ability problems. These problems can be solved by changing the processing to hot

www.metalformingmagazine.com

METALFORMING / DECEMBER 2010 21

Generation 1