Page 26 - MetalForming September 2009

P. 26

Tooling Technology

Peter Ulintz has worked in the sheetmetal-forming industry since 1978. His background includes tool and die making, tool and process engineering, engineering management and product devel- opment. Peter also operates the website ToolingbyDesign.com, a source for the transfer of modern metalforming and tool-and-die technology, and which promotes the use of “Performance-Based Die Engineering Strategies.”

Peter speaks at PMA seminars and roundtables focusing on tool and die design, die maintenance, deep drawing, stamping simula- tion, tooling for stamping high- strength steels and problem solv- ing in the press shop.

Peter Ulintz pete.ulintz@toolingbydesign.com www.toolingbydesign.com

Aforce is required to remove the sheetmetal from around the punch steel in a cutting die. The action is referred to as “stripping” and the device is called a stripper plate.

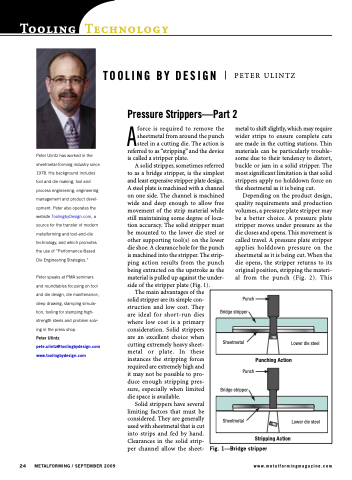

A solid stripper, sometimes referred to as a bridge stripper, is the simplest and least expensive stripper plate design. A steel plate is machined with a channel on one side. The channel is machined wide and deep enough to allow free movement of the strip material while still maintaining some degree of loca- tion accuracy. The solid stripper must be mounted to the lower die steel or other supporting tool(s) on the lower die shoe. A clearance hole for the punch is machined into the stripper. The strip- ping action results from the punch being extracted on the upstroke as the material is pulled up against the under- side of the stripper plate (Fig. 1).

The main advantages of the solid stripper are its simple con- struction and low cost. They are ideal for short-run dies where low cost is a primary consideration. Solid strippers are an excellent choice when cutting extremely heavy sheet- metal or plate. In these instances the stripping forces required are extremely high and it may not be possible to pro- duce enough stripping pres- sure, especially when limited die space is available.

Solid strippers have several limiting factors that must be considered. They are generally used with sheetmetal that is cut into strips and fed by hand. Clearances in the solid strip- per channel allow the sheet-

PETER ULINTZ

metal to shift slightly, which may require wider strips to ensure complete cuts are made in the cutting stations. Thin materials can be particularly trouble- some due to their tendency to distort, buckle or jam in a solid stripper. The most significant limitation is that solid strippers apply no holddown force on the sheetmetal as it is being cut.

Depending on the product design, quality requirements and production volumes, a pressure plate stripper may be a better choice. A pressure plate stripper moves under pressure as the die closes and opens. This movement is called travel. A pressure plate stripper applies holddown pressure on the sheetmetal as it is being cut. When the die opens, the stripper returns to its original position, stripping the materi- al from the punch (Fig. 2). This

Punch Bridge stripper

Punch

Bridge stripper

Punching Action

Sheetmetal

Sheetmetal

Lower die steel

Stripping Action

Lower die steel

24 METALFORMING / SEPTEMBER 2009

www.metalformingmagazine.com

TOOLING BY DESIGN Pressure Strippers—Part 2

Fig. 1—Bridge stripper