Page 34 - MetalForming April 2009

P. 34

Tooling Technology

Stuart Keeler (Keeler Technologies LLC) is best known worldwide for his discovery of forming limit diagrams, development of circle grid analysis and implementation of other press shop analysis tools. Stuart’s sheetmetal forming experience includes 24 years at National Steel Corporation and

12 years at The Budd Company Technical Center, enabling him to bring a very diverse background to this column and the many seminars he teaches for PMA. His most recent project is technical editor of the AHSS Application Guidelines—Version 4.

Keeler Technologies LLC

P.O. Box 283

Grosse Ile, MI 48138

Fax: 734/671-2271

E-mail: keeltech@comcast.net

Stuart’s next seminars are:

• Higher Strength Steels— Solving the Problems on April 15 in Chicago, IL.

• Troubleshooting Formability Problems on May 7 in Indi- anapolis, IN.

Check www.metalforming.com for these and other seminars.

On March 15, 2009, WorldAutoSteel, the automotive group of the World Steel Association, announced the release of the Advanced High Strength Steel (AHSS) Application Guidelines— Version 4.0. More than 150 pages and 120 figures and graphics not only con- tain the metallurgy, forming and joining of these unique steels, but allow com- parison of their characteristics to tra- ditional higher-strength steels. Includ- ed is a glossary defining 125 terms encompassing many areas of sheetmet- al and dies. This document provides additional information for this month’s feature article, Forming Higher-Strength Steels, beginning on page 16. While this document is targeted for the automotive industry, steel follows the laws of physics and therefore the information is indus- try independent.

Attention OEMs, steel service cen- ters, product designers, process design- ers, die designers, die-build facilities, Tier One, Two and Three suppliers, and others in the sheetmetal-forming indus- try. Are you ready when the purchase order arrives specifying that the part must be made with an AHSS? Some are already processing these steels. Many more will be facing this task in the near future.

included adding carbon or other ele- ments to raise the strength of the steel. Another method was to coldwork the steel (full hard) and then often partial- ly anneal the steel (3⁄4 hard, 1⁄2 hard, etc.). These were less expensive methods to obtain high strength but the stretch- ability and bendability of the steels were greatly reduced. The HSLA (high- strength low-alloy) steels have been the primary high-strength steels over the last 30 to 35 years. Produced by thermal mechanical processing, HSLA grades have yield strengths from 35 to 80 ksi (240-550 MPa). Now some HSLA steels have yield strengths of 100 and 110 ksi (690-750 MPa). Other traditional high- strength steels are C-Mn (carbon man- ganese), BH (bake hardenable), and IF- HS (interstitial-free high-strength).

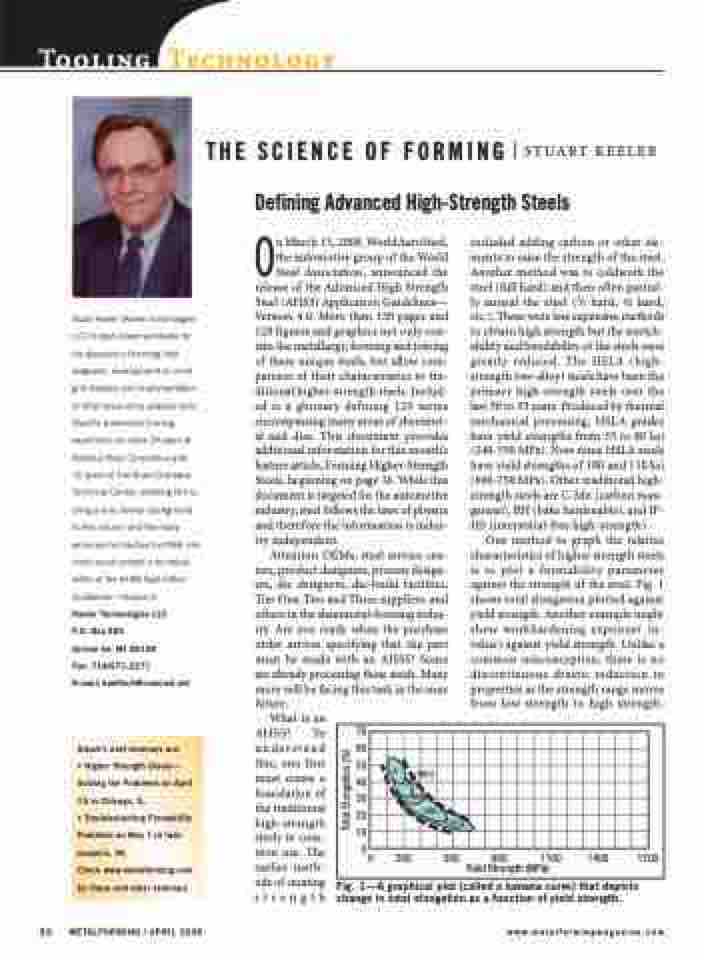

One method to graph the relative characteristics of higher strength steels is to plot a formability parameter against the strength of the steel. Fig. 1 shows total elongation plotted against yield strength. Another example might show workhardening exponent (n- value) against yield strength. Unlike a common misconception, there is no discontinuous drastic reduction in properties as the strength range moves from low strength to high strength.

THE SCIENCE OF FORMING Defining Advanced High-Strength Steels

What is an AHSS? To understand this, one first must create a foundation of the traditional high-strength steels in com- mon use. The earlier meth- ods of creating strength

Fig. 1—A graphical plot (called a banana curve) that depicts change in total elongation as a function of yield strength.

STUART KEELER

70

60

50

40

30

20

10

0

0 200 500 800 1100 1400 1700

Yield Strength (MPa)

IF

BH

MILD

CMn

HSLA

32 METALFORMING / APRIL 2009

www.metalformingmagazine.com

Total Elongation (%)