Page 23 - MetalForming April 2009

P. 23

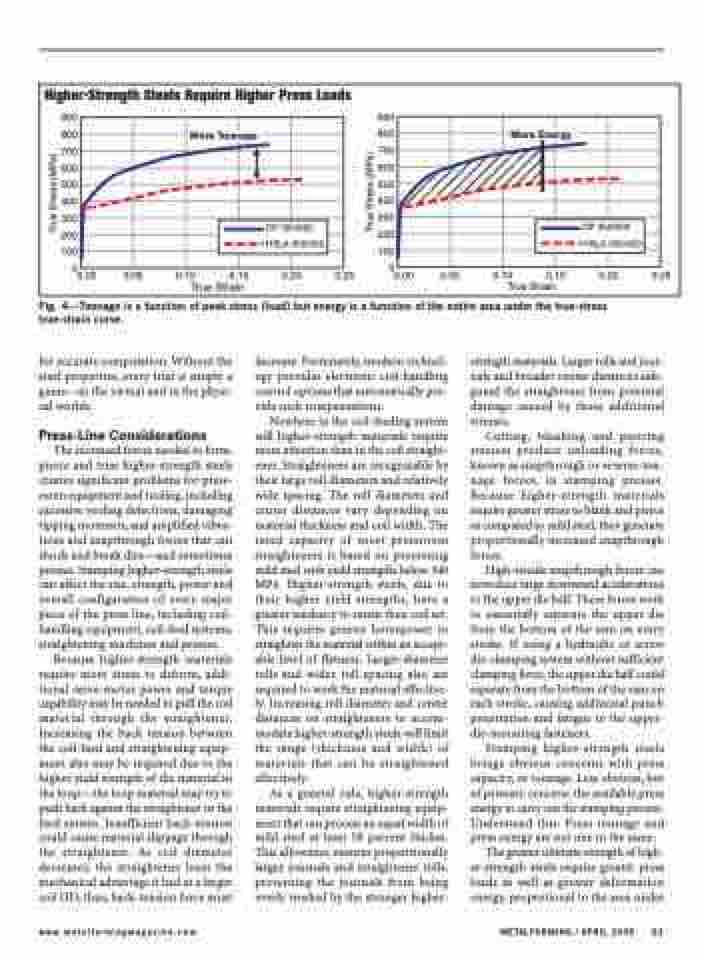

Higher-Strength Steels Require Higher Press Loads

900 900 800 800 700 700 600 600 500 500 400 400 300 300 200 200 100 100

00.00 0.05 0.10 0.15 0.20 0.25 00.00 0.05 0.10 0.15 0.20 0.25 True Strain True Strain

More Energy

DP 35

0/600

HSLA

350/450

More Tonnage

DP 35

0/600

HSLA

350/450

Fig. 4—Tonnage is a function of peak stress (load) but energy is a function of the entire area under the true-stress true-strain curve.

for accurate computation. Without the steel properties, every trial is simply a guess—in the virtual and in the physi- cal worlds.

Press-Line Considerations

The increased forces needed to form, pierce and trim higher-strength steels creates significant problems for press- room equipment and tooling, including excessive tooling defections, damaging tipping moments, and amplified vibra- tions and snapthrough forces that can shock and break dies—and sometimes presses. Stamping higher-strength steels can affect the size, strength, power and overall configuration of every major piece of the press line, including coil- handling equipment, coil-feed systems, straightening machines and presses.

Because higher-strength materials require more stress to deform, addi- tional servo-motor power and torque capability may be needed to pull the coil material through the straightener. Increasing the back tension between the coil-feed and straightening equip- ment also may be required due to the higher yield strength of the material in the loop—the loop material may try to push back against the straightener or the feed system. Insufficient back-tension could cause material slippage through the straightener. As coil diameter decreases, the straightener loses the mechanical advantage it had at a larger coil OD; thus, back-tension force must

decrease. Fortunately, modern technol- ogy provides electronic coil-handling control options that automatically pro- vide such compensations.

Nowhere in the coil-feeding system will higher-strength materials require more attention than in the coil straight- ener. Straighteners are recognizable by their large roll diameters and relatively wide spacing. The roll diameters and center distances vary depending on material thickness and coil width. The rated capacity of most pressroom straighteners is based on processing mild steel with yield strengths below 340 MPa. Higher-strength steels, due to their higher yield strengths, have a greater tendency to retain their coil set. This requires greater horsepower to straighten the material within an accept- able level of flatness. Larger-diameter rolls and wider roll spacing also are required to work the material effective- ly. Increasing roll diameter and center distances on straighteners to accom- modate higher-strength steels will limit the range (thickness and width) of materials that can be straightened effectively.

As a general rule, higher-strength materials require straightening equip- ment that can process an equal width of mild steel at least 50 percent thicker. This allowance ensures proportionally larger journals and straightener rolls, preventing the journals from being overly worked by the stronger higher-

strength materials. Larger rolls and jour- nals and broader center distances safe- guard the straightener from potential damage caused by these additional stresses.

Cutting, blanking and piercing stresses produce unloading forces, known as snapthrough or reverse-ton- nage forces, in stamping presses. Because higher-strength materials require greater stress to blank and pierce as compared to mild steel, they generate proportionally increased snapthrough forces.

High-tensile snapthrough forces can introduce large downward accelerations to the upper die half. These forces work to essentially separate the upper die from the bottom of the ram on every stroke. If using a hydraulic or screw die-clamping system without sufficient clamping force, the upper die half could separate from the bottom of the ram on each stroke, causing additional punch penetration and fatigue to the upper- die-mounting fasteners.

Stamping higher-strength steels brings obvious concerns with press capacity, or tonnage. Less obvious, but of primary concern: the available press energy to carry out the stamping process. Understand this: Press tonnage and press energy are not one in the same.

The greater ultimate strength of high- er-strength steels require greater press loads as well as greater deformation energy, proportional to the area under

www.metalformingmagazine.com

METALFORMING / APRIL 2009 21

True Stress (MPa)

True Stress (MPa)