Page 15 - MetalForming December 2019

P. 15

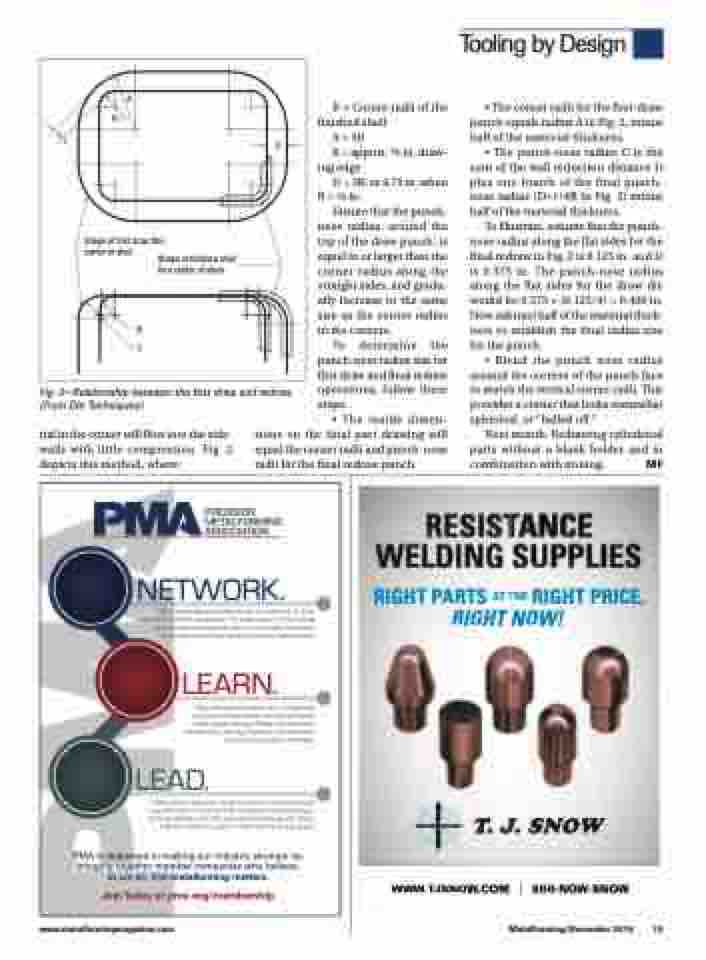

Fig. 2—Relationship between the first draw and redraw (from Die Techniques)

D=3R;or0.75in.when R > 1⁄2 in.

Ensure that the punch- nose radius, around the top of the draw punch, is equal to or larger than the corner radius along the straight sides, and gradu- ally increase to the same size as the corner radius in the corners.

To determine the punch-nose radius size for first draw and final redraw operations, follow these steps:

rial in the corner will flow into the side- walls with little compression. Fig. 2 depicts this method, where:

• The inside dimen- sions on the final part drawing will equal the corner radii and punch-nose

radii for the final redraw punch.

RESIS

WELDIN

A = 5R

X = approx. ing edge

1

⁄8-in. draw-

Tooling by Design

x

A R

Shape of first draw thru

D

center of shell

B C

Shape of finished shell thru center of stock

R = Corner radii of the finished shell

• The corner radii for the first-draw punch equals radius A in Fig. 2, minus half of the material thickness.

• The punch-nose radius C is the sum of the wall reduction distance D plus one-fourth of the final punch- nose radius (D+1/4B in Fig. 2) minus half of the material thickness.

To illustrate, assume that the punch- nose radius along the flat sides for the final redraw in Fig. 2 is 0.125 in. and D is 0.375 in. The punch-nose radius along the flat sides for the draw die would be 0.375 + (0.125/4) = 0.406 in. Now subtract half of the material thick- ness to establish the final radius size for the punch.

• Blend the punch nose radius around the corners of the punch face to match the vertical corner radii. This provides a corner that looks somewhat spherical, or “balled off.”

Next month: Redrawing cylindrical parts without a blank holder and in combination with ironing. MF

NETWORK.

PMA membership provides access to a network of more than 800 member companies. The wide variety of networking opportunities and platforms allow you to make meaningful connections and foster valuable business relationships.

LEARN.

PMA membership allows you to share best practices and learn about emerging industry technologies through PMA’s executive-level conferences, training programs, exclusive plant tours and local district meetings.

LEAD.

PMA actively leads the charge for small and medium-sized manufacturers on policies that strengthen manufacturing in America. Benefit from the association’s lobbying and media- relations efforts in support of pro-manufacturing issues.

PMA is dedicated to making our industry stronger by bringing together member companies who believe, as we do, that metalforming matters.

JoinToday at pma.org/membership

S

T

T

T

T

A

A

A

A

N

NCE

G SUPPLIE

G

S

S

RIGHT P

ARTS A

RIGHT NOW!

A

T THE RIGHT PRICE,

T

www.metalformingmagazine.com

MetalForming/December 2019 13

WWW.TJSNOW.COM | 800-NOW-SNOW