Page 36 - MetalForming July 2019

P. 36

Fabrication: Welding Well

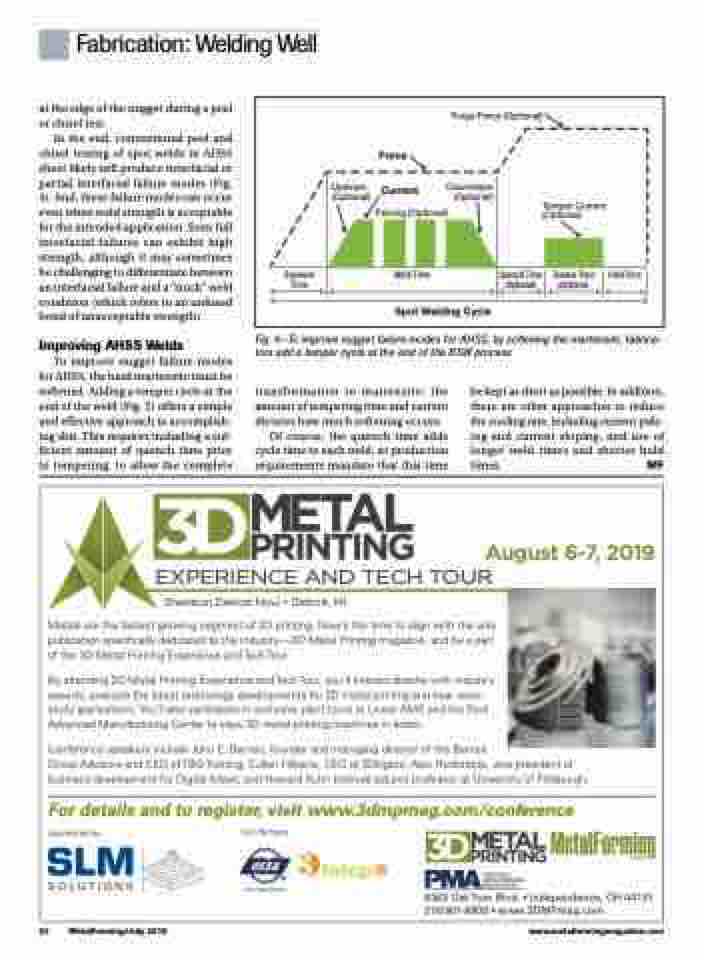

Forge Force (Optional)

Upslope (Optional)

Force

Current Downslope

(Optional)

Pulsing (Optional)

Temper Current (Optional)

Squeeze Time

Weld Time

Quench Time (Optional)

Temper Time (Optional)

Hold Time

Spot Welding Cycle

at the edge of the nugget during a peel or chisel test.

In the end, conventional peel and chisel testing of spot welds in AHSS sheet likely will produce interfacial or partial interfacial failure modes (Fig. 4). And, these failure modes can occur even when weld strength is acceptable for the intended application. Even full interfacial failures can exhibit high strength, although it may sometimes be challenging to differentiate between an interfacial failure and a “stuck” weld condition (which refers to an unfused bond of unacceptable strength).

Improving AHSS Welds

To improve nugget failure modes for AHSS, the hard martensite must be softened. Adding a temper cycle at the end of the weld (Fig. 5) offers a simple and effective approach to accomplish- ing this. This requires including a suf- ficient amount of quench time prior to tempering, to allow the complete

Fig. 5—To improve nugget failure modes for AHSS, by softening the martensite, fabrica- tors add a temper cycle at the end of the RSW process.

transformation to martensite; the amount of tempering time and current dictates how much softening occurs.

Of course, the quench time adds cycle time to each weld, so production requirements mandate that this time

be kept as short as possible. In addition, there are other approaches to reduce the cooling rate, including current puls- ing and current sloping, and use of longer weld times and shorter hold times. MF

August 6-7, 2019

EXPERIENCE AND TECH TOUR Sheraton Detroit Novi • Detroit, MI

Metals are the fastest growing segment of 3D printing. Now’s the time to align with the only publication specifically dedicated to the industry—3D Metal Printing magazine, and be a part of the 3D Metal Printing Experience and Tech Tour.

By attending 3D Metal Printing Experience and Tech Tour, you’ll interact directly with industry experts, evaluate the latest technology developments for 3D metal printing and hear case- study applications. You’ll also participate in exclusive plant tours at Linear AMS and the Ford Advanced Manufacturing Center to view 3D metal-printing machines in action.

Conference speakers include John E. Barnes, founder and managing director of the Barnes

Group Advisors and CEO of TBG Training; Cullen Hilkene, CEO of 3Diligent; Alex Huckstepp, vice president of business development for Digital Alloys; and Howard Kuhn (retired) adjunct professor at University of Pittsburgh.

For details and to register, visit www.3dmpmag.com/conference

Sponsored by: Our Partners:

6363 OakTree Blvd. • Independence, OH 44131 216/901-8800 • www.3DMPmag.com

34 MetalForming/July 2019

www.metalformingmagazine.com