Page 34 - MetalForming July 2019

P. 34

FABRICATION

Automotive AHSS

The subject of modern advanced high strength steels (AHSS) requires a thorough review of the processing, metallurgy and microstructures, prior to discussing approaches to resistance spot welding (RSW).

BY MENACHEM KIMCHI

Compared to conventional steels, advanced high strength steels (AHSS) contain higher alloy addi- tions with complex microstructures con- sisting of multiple phases. All AHSS grades rely on some combination of processing at high temperatures (thermomechanical processing) in the austenite phase field, followed by controlled cooling. The ability to combine alloying with thermomechan- ical processing allows steelmakers to cus- tomize microstructures, and, therefore, customize material properties to optimally combine strength and ductility. Further, AHSS grades attain additional strength by strain hardening.

The numerous AHSS families offer strengths ranging from approximately 500 to more than 2000 MPa, and percentage elongations as high as 60 percent to less than 10 percent. Here, we address following AHSS grades: TRIP (transformation-induced plasticity); DP (dual phase); CP (complex phase); MS (martensitic); TWIP (twinning- induced plasticity); and HF (hot formed) steels. These steels typically are classified

Menachem Kimchi, M.Sc. Welding Engineer- ing, is an associate professor in the Depart- ment of Material Science & Engineering, Welding Engineering Program at The Ohio State University, Columbus, OH.

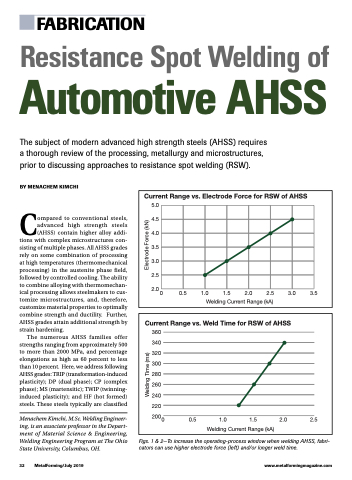

Figs. 1 & 2—To increase the operating-process window when welding AHSS, fabri- cators can use higher electrode force (left) and/or longer weld time.

Current Range vs. Electrode Force for RSW of AHSS

5.0 4.5 4.0 3.5 3.0 2.5 2.0

0 0.5

1.0 1.5 2.0 2.5 Welding Current Range (kA)

3.0 3.5

Current Range vs. Weld Time for RSW of AHSS

360 340 320 300 280 260 240 220 200 0

0.5 1.0

Welding Current Range (kA)

1.5 2.0 2.5

32 MetalForming/July 2019

www.metalformingmagazine.com

Welding Time (ms) Electrode Force (kN)