Page 39 - MetalForming May 2019

P. 39

The Greening of Resistance Welding

BY TOM SNOW

What if you were only allowed to run your resistance weld- ing (RW) machine during the middle of the night?

That happened to one manufacturer in a small Iowa community several years ago when it installed a large 300- kVA single-phase AC press-type RW machine in what once was a retail building that lacked adequate incom- ing power. Daytime operation of the machine was quickly banned by the local power company due to com- plaints received from locals who expe- rienced flickering lights and TVs when the machine ran.

Single-Phase vs. Three-Phase

Although engineers at companies new to the RW process often assume that all machines are wired for three- phase operation, most of the machines in use, outside of the aerospace indus- try, have been single-phase for decades.

Single-phase RW machines, con- nected to only two of the three legs of an incoming three-phase service, can cause problems because they require a large and instantaneous primary amperage draw to operate properly. In addition, the power factor or efficiency

Tom Snow is chairman of T. J. Snow Co., Chattanooga, TN, a supplier of resistance-welding machines, supplies, service and training: www.tjsnow.com.

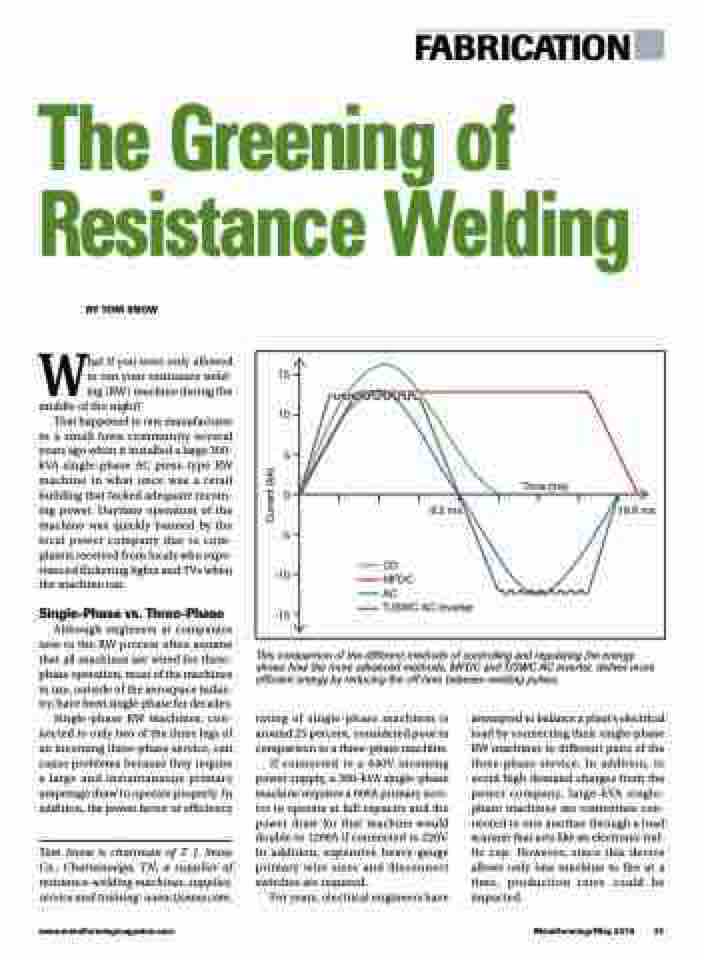

This comparison of the different methods of controlling and regulating the energy shows how the more advanced methods, MFDC and TJSWC AC inverter, deliver more efficient energy by reducing the off time between welding pulses.

FABRICATION

15

10

5

0

-5

-10

-15

Time (ms)

8.3 ms

CD

MFDC

AC

TJSWC AC Inverter

16.6 ms

rating of single-phase machines is around 25 percent, considered poor in comparison to a three-phase machine.

If connected to a 440V incoming power supply, a 300-kVA single-phase machine requires a 600A primary serv- ice to operate at full capacity and the power draw for that machine would double to 1200A if connected to 220V. In addition, expensive heavy-gauge primary wire sizes and disconnect switches are required.

For years, electrical engineers have

attempted to balance a plant’s electrical load by connecting their single-phase RW machines to different pairs of the three-phase service. In addition, to avoid high demand charges from the power company, large-kVA single- phase machines are sometimes con- nected to one another through a load scanner that acts like an electronic traf- fic cop. However, since this device allows only one machine to fire at a time, production rates could be impacted.

www.metalformingmagazine.com

MetalForming/May 2019 37

Current (kA)