Page 42 - MetalForming-January-2019-issue

P. 42

The Science of Forming

By Daniel J. Schaeffler, Ph.D.

Beyond the TYE: Uniform Elongation and n-Value

Acertification of metal properties should arrive with every steel or aluminum shipment. You may know these as metal certs, or YTEs or TYEs, as they list the material’s yield strength, tensile strength and elongation, measured in one tensile test likely taken from the end of a mile-long coil. Minimum requirements for yield, tensile and elongation possibly exist in the specification to which a user ordered the material. Check that these specifications conform with requirements. However, other properties measured in the tensile test better characterize sheetmetal formability.

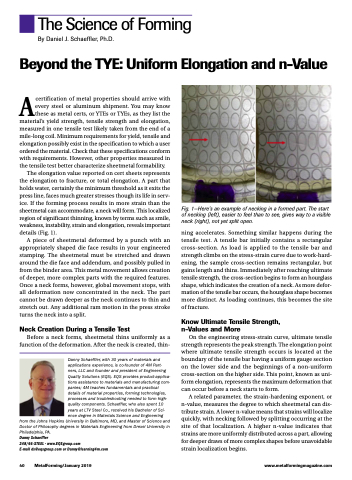

The elongation value reported on cert sheets represents the elongation to fracture, or total elongation. A part that holds water, certainly the minimum threshold as it exits the press line, faces much greater stresses though its life in serv- ice. If the forming process results in more strain than the sheetmetal can accommodate, a neck will form. This localized region of significant thinning, known by terms such as smile, weakness, instability, strain and elongation, reveals important details (Fig. 1).

A piece of sheetmetal deformed by a punch with an appropriately shaped die face results in your engineered stamping. The sheetmetal must be stretched and drawn around the die face and addendum, and possibly pulled in from the binder area. This metal movement allows creation of deeper, more complex parts with the required features. Once a neck forms, however, global movement stops, with all deformation now concentrated in the neck. The part cannot be drawn deeper as the neck continues to thin and stretch out. Any additional ram motion in the press stroke turns the neck into a split.

Neck Creation During a Tensile Test

Before a neck forms, sheetmetal thins uniformly as a function of the deformation. After the neck is created, thin-

Danny Schaeffler, with 30 years of materials and applications experience, is co-founder of 4M Part- ners, LLC and founder and president of Engineering Quality Solutions (EQS). EQS provides product-applica- tions assistance to materials and manufacturing com- panies; 4M teaches fundamentals and practical details of material properties, forming technologies, processes and troubleshooting needed to form high- quality components. Schaeffler, who also spent 10 years at LTV Steel Co., received his Bachelor of Sci- ence degree in Materials Science and Engineering

from the Johns Hopkins University in Baltimore, MD, and Master of Science and Doctor of Philosophy degrees in Materials Engineering from Drexel University in Philadelphia, PA.

Danny Schaeffler

248/66-STEEL • www.EQSgroup.com

E-mail ds@eqsgroup.com or Danny@learning4m.com

Fig. 1—Here’s an example of necking in a formed part. The start of necking (left), easier to feel than to see, gives way to a visible neck (right), not yet split open.

ning accelerates. Something similar happens during the tensile test. A tensile bar initially contains a rectangular cross-section. As load is applied to the tensile bar and strength climbs on the stress-strain curve due to work-hard- ening, the sample cross-section remains rectangular, but gains length and thins. Immediately after reaching ultimate tensile strength, the cross-section begins to form an hourglass shape, which indicates the creation of a neck. As more defor- mation of the tensile bar occurs, the hourglass shape becomes more distinct. As loading continues, this becomes the site of fracture.

Know Ultimate Tensile Strength, n-Values and More

On the engineering stress-strain curve, ultimate tensile strength represents the peak strength. The elongation point where ultimate tensile strength occurs is located at the boundary of the tensile bar having a uniform gauge section on the lower side and the beginnings of a non-uniform cross-section on the higher side. This point, known as uni- form elongation, represents the maximum deformation that can occur before a neck starts to form.

A related parameter, the strain-hardening exponent, or n-value, measures the degree to which sheetmetal can dis- tribute strain. A lower n-value means that strains will localize quickly, with necking followed by splitting occurring at the site of that localization. A higher n-value indicates that strains are more uniformly distributed across a part, allowing for deeper draws of more complex shapes before unavoidable strain localization begins.

40 MetalForming/January 2019

www.metalformingmagazine.com