Page 42 - MetalForming February 2013

P. 42

Automation Package

Automating its new high-power laser-cutting machine with a nozzle changer, beam-alignment unit and sheet handler positions this OEM manufacturer to grow its contract sheet- and plate-fabrication business.

BY BRAD F. KUVIN, EDITOR

Best practices for laser cutting call for matching the right assist-gas nozzle diameter to the laser output power and assist-gas type and pressure, based on workpiece material type and thickness. Fail to do so and not only will cutting speed suffer, but—more importantly—so will cut quality and, ultimately, customer satisfaction. Typical nozzle diameters range from 0.8 to 3 mm.

Nozzle Diameter for Laser Cutting Mild and Stainless Steels

From “Facts About Laser Cutting,” Linde AG

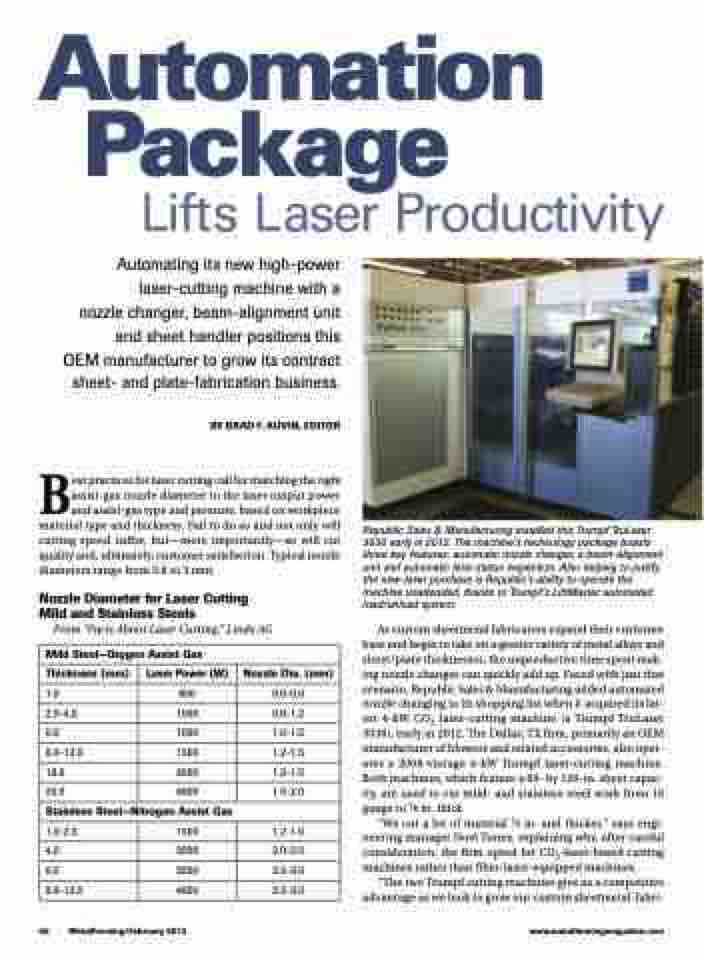

Republic Sales & Manufacturing installed this Trumpf TruLaser 3030 early in 2012. The machine’s technology package boasts three key features: automatic nozzle changer, a beam-alignment unit and automatic lens-status inspection. Also helping to justify the new-laser purchase is Republic’s ability to operate the machine unattended, thanks to Trumpf’s LiftMaster automated load/unload system.

As custom sheetmetal fabricators expand their customer base and begin to take on a greater variety of metal alloys and sheet/plate thicknesses, the unproductive time spent mak- ing nozzle changes can quickly add up. Faced with just that scenario, Republic Sales & Manufacturing added automated nozzle changing to its shopping list when it acquired its lat- est 4-kW CO2 laser-cutting machine (a Trumpf TruLaser 3030), early in 2012. The Dallas, TX firm, primarily an OEM manufacturer of blowers and related accessories, also oper- ates a 2008-vintage 4-kW Trumpf laser-cutting machine. Both machines, which feature a 60- by 120-in. sheet capac- ity, are used to cut mild- and stainless-steel work from 16 gauge to 3⁄8 in. thick.

“We cut a lot of material 1⁄4 in. and thicker,” says engi- neering manager Noel Torres, explaining why, after careful consideration, the firm opted for CO2-laser-based cutting machines rather than fiber-laser-equipped machines.

“The two Trumpf cutting machines give us a competitive advantage as we look to grow our custom sheetmetal-fabri-

Mild Steel—Oxygen Assist Gas

Thickness (mm)

Laser Power (W)

Nozzle Dia. (mm)

1.0

800

0.6-0.8

2.0-4.0

1000

0.6-1.2

6.0

1000

1.0-1.5

8.0-12.0

1500

1.2-1.5

18.0

2000

1.2-1.5

25.0

4000

1.5-2.0

Stainless Steel—Nitrogen Assist Gas

1.0-2.0

1500

1.2-1.5

4.0

3000

2.0-2.5

6.0

3000

2.5-3.0

9.0-12.0

4000

2.5-3.0

40

MetalForming/February 2013

www.metalformingmagazine.com