Peter Ulintz

Peter UlintzThe History of D2 Tool Steel…According to Research

February 8, 2024Comments

In last month’s Tooling by Design column, “The History of D2 Tool Steel…According to ChatGPT,” I used readily available artificial-intelligence (AI) software (ChatGPT 4.0) to ask, “When was D2 tool steel invented and by whom?” I felt strange engaging in conversation with a chatbot, but it was a fun and mostly comical experience, albeit the AI responses proved unreliable and inaccurate.

This month, I’ll explore the history of D2 tool steel using traditional means … research.

Early Tool Steels

Tool steel refers to any steel used to make tools for cutting, forming, or otherwise shaping a material into a part or component for a specific use. The earliest tool steels were simple, plain carbon steels. Beginning in 1868, and increasingly into the 20th century, material innovators developed many complex and highly alloyed steels to meet severe service demands and provide freedom from cracking during heat treatment.

Tool steel refers to any steel used to make tools for cutting, forming, or otherwise shaping a material into a part or component for a specific use. The earliest tool steels were simple, plain carbon steels. Beginning in 1868, and increasingly into the 20th century, material innovators developed many complex and highly alloyed steels to meet severe service demands and provide freedom from cracking during heat treatment.

In 1868, British metallurgist Robert Forester Mushet offered the first commercially produced tool steel. Mushet steel, also known as Robert Mushet’s Special Steel, was tabbed as the first “self-hardening”—and later, “air-hardening”—steel because it could be fully hardened in still air. Prior to Mushet’s discovery, hardening steel required quenching in water or oil.

Alloy Steels

ASTM A681 Standard Specification for Tool Steels Alloy classifies three categories of cold-work tool steel: air-hardening steels (group A); high-carbon, high-chromium steels (group D); and oil-hardening steels (group O).

Development of D2, part of group D, likely would coincide with the invention of other chromium-alloyed steels such as stainless steel and high-speed steel. Chromium-alloyed steel production did not become practical until the development of ferrochromium by Pierre Berthier in 1821 and, more practically, in 1895 with the development of low-carbon ferrochromium. In 1861, Mushet reported the first commercially produced steel with a chromium addition.

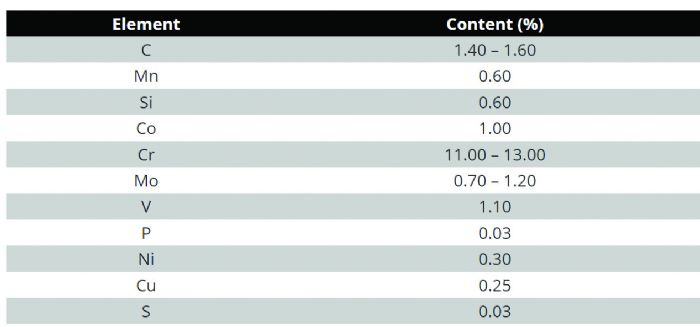

The patent makes several claims related to composition, including “an alloy steel containing carbon about 1.4 to 1.6%, chromium about 11.5 to 12.5%, vanadium about 0.75 to 1.25%, molybdenum about 0.75 to 1.25%, and having the capability for air hardening even in fairly large sections to over 600 Brinell and the capability for being annealed to a softness below 210 Brinell.”

The patent makes several claims related to composition, including “an alloy steel containing carbon about 1.4 to 1.6%, chromium about 11.5 to 12.5%, vanadium about 0.75 to 1.25%, molybdenum about 0.75 to 1.25%, and having the capability for air hardening even in fairly large sections to over 600 Brinell and the capability for being annealed to a softness below 210 Brinell.”