Page 44 - MetalForming April 2020

P. 44

The Science of Forming

By Daniel J. Schaeffler, Ph.D.

Coming Soon: AHSS Application Guidelines,

Online and Updated

Advanced high-strength steels (AHSS) find use in nearly every vehicle on the market. Near-term projections indicate that these grades will soon comprise 60 per- cent of the typical automotive body structure. While these new steels offer many beneficial characteristics, they behave differently from other grades during forming and joining, and, therefore, require metal formers and other manufac- turers to master the fundamentals and keep pace with process improvements being realized on the shop floor.

To guide users of these new and emerging products and help them navigate through these challenges, 22 steelmakers from around the world have been working together. Under the umbrella of WorldAutoSteel, they developed, nearly two decades ago, the Advanced High Strength Steels Application Guidelines, as early AHSS grades began transitioning from research to commercialization. In 2017, WorldAutoSteel released Version 6 of this document, which explains the unique characteristics of each grade, and presents global best practices for forming and joining AHSS.

The next update of the guidelines, expected to be com- pleted in 2021, will transform them into a mobile-friendly online database, which users can browse and search in order to quickly find specific information of interest. WorldAu- toSteel will release the content to the public in several phases during the next 18 months. Even then, the knowledge data- base will never be truly complete. Having content posted online allows for uploading new and pertinent information as it becomes available, making the AHSS Application Guide- lines a useful reference well into the future.

Updated Materials Portfolio

The new guidelines will contain a materials portfolio, listing available grades as well as those projected to be com- mercially available by 2021. The number of AHSS grades has more than doubled from the 20 listed in Version 4.1, released in 2009, expanding to higher levels of strength and

Dr. Danny Schaeffler, with 30 years of materials and applications experience, is president of Engineering Quality Solutions (EQS) and Chief Content Officer of 4M Partners. EQS provides product-applications assistance to materials and manufacturing compa- nies; 4M teaches fundamentals and practical details of material properties, forming technologies, process- es and troubleshooting needed to form high-quality components. Schaeffler is the Metallurgy and Form- ing Technical Editor of the next release of the AHSS Applications Guidelines available from WorldAutoSteel.

Danny Schaeffler

248/66-STEEL • www.EQSgroup.com

E-mail ds@eqsgroup.com or Danny@learning4m.com

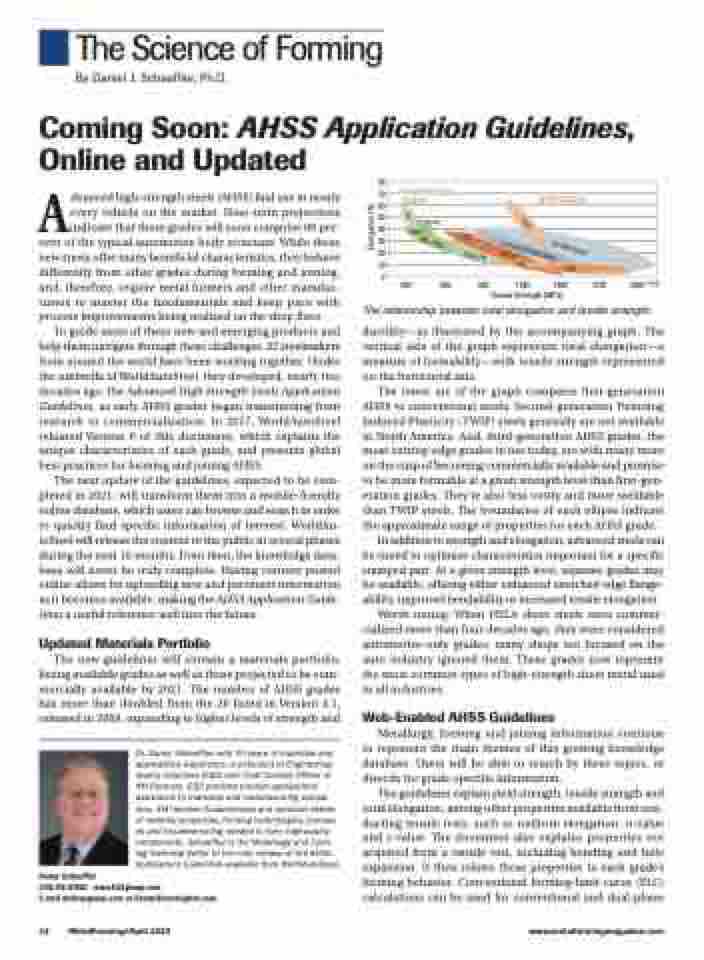

The relationship between total elongation and tensile strength.

ductility—as illustrated by the accompanying graph. The vertical axis of the graph represents total elongation—a measure of formability—with tensile strength represented on the horizontal axis.

The lower arc of the graph compares first-generation AHSS to conventional steels. Second-generation Twinning Induced Plasticity (TWIP) steels generally are not available in North America. And, third-generation AHSS grades, the most cutting-edge grades in use today, are with many more on the cusp of becoming commercially available and promise to be more formable at a given strength level than first-gen- eration grades. They’re also less costly and more weldable than TWIP steels. The boundaries of each ellipse indicate the approximate range of properties for each AHSS grade.

In addition to strength and elongation, advanced steels can be tuned to optimize characteristics important for a specific stamped part. At a given strength level, separate grades may be available, offering either enhanced stretched edge flange- ability, improved bendability or increased tensile elongation.

Worth noting: When HSLA sheet steels were commer- cialized more than four decades ago, they were considered automotive-only grades; many shops not focused on the auto industry ignored them. These grades now represent the most common types of high-strength sheet metal used in all industries.

Web-Enabled AHSS Guidelines

Metallurgy, forming and joining information continue to represent the main themes of this growing knowledge database. Users will be able to search by these topics, or directly for grade-specific information.

The guidelines explain yield strength, tensile strength and total elongation, among other properties available from con- ducting tensile tests, such as uniform elongation, n-value and r-value. The document also explains properties not acquired from a tensile test, including bending and hole expansion. It then relates these properties to each grade’s forming behavior. Conventional forming-limit-curve (FLC) calculations can be used for conventional and dual-phase

80 70 60 50 40 30 20 10

0

200 500

800 1100 1400 Tensile Strength (MPa)

1700 2000

CONVENTIONAL

STEELS AHSS GRADES

IF

Mild BH

IF-HS

MS

PHS

42 MetalForming/April 2020

www.metalformingmagazine.com

Elongation (%)

TWIP

TRIP

CMn+

3rd GEN AHSS Current 3rd GEN AHSS

DP, CP

HSLA, FB