Page 35 - MetalForming April 2020

P. 35

13Remove all notes and dimensions.

It’s common for vector-design files to include dimensions, gridlines, notes and other information in addition to the part design. Remove all of these extras from the design file before sending it to a laser house so that they won’t be included in the instant-quoting process. Instead, include additional notes for the contract shop in a separate PDF

sent along with the design files.

14Think about transport and shipping.

When designing the vector file for laser cutting, consider how the end product will be transported to the final desti- nation. Shipping larger parts can be challenging; most freight carriers have a maximum pallet size of 4 by 8 ft. Conversely, UPS and FedEx can readily ship parts smaller than 4 by 4 ft.

and that weigh less than 60 lb.

15

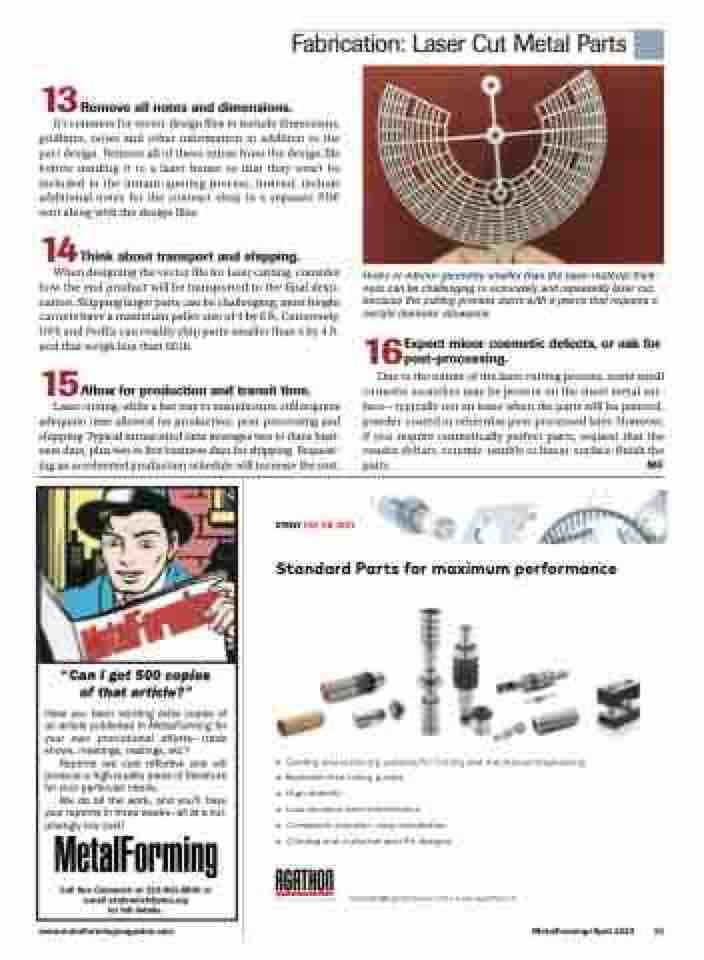

Holes or interior geometry smaller than the base-material thick- ness can be challenging to accurately and repeatedly laser cut, because the cutting process starts with a pierce that requires a certain diameter allowance.

16Expect minor cosmetic defects, or ask for post-processing.

Due to the nature of the laser cutting process, some small cosmetic scratches may be present on the sheet metal sur- face—typically not an issue when the parts will be painted, powder-coated or otherwise post-processed later. However, if you require cosmetically perfect parts, request that the vendor deburr, ceramic-tumble or linear-surface-finish the parts. MF

Allow for production and transit time.

Laser cutting, while a fast way to manufacture, still requires adequate time allowed tor production, post-processing and shipping. Typical turnaround time averages two to three busi- ness days, plus two to five business days for shipping. Request- ing an accelerated production schedule will increase the cost.

Fabrication: Laser Cut Metal Parts

“Can I get 500 copies

of that article?”

Have you been wanting extra copies of an article published in MetalForming for your own promotional efforts—trade shows, meetings, mailings, etc?

Reprints are cost effective and will produce a high-quality piece of literature for your particular needs.

We do all the work, and you’ll have your reprints in three weeks—all at a sur- prisingly low cost!

Call Sue Cubranich at 216-901-8800 or e-mail scubranich@pma.org

for full details.

Standard Parts for maximum performance

● Guiding and centering systems for tooling and mechanical engineering

● Backlash-free rolling guides

● High stability

● Low abrasion and maintenance

● Consistent precision, easy installation

● Catalog and customer specific designs

www.metalformingmagazine.com

MetalForming/April 2020 33

mailamt@agathonusa.com | www.agathon.ch