Page 89 - MetalForming October 2019

P. 89

mechanism that had been rely- ing on an old servo-valve con- troller—obsolete for many years, according to Brian Marion, a mechanical engineer at Catalina Cylinders. While the mechanism had run without major issues of its own, at times operators would need to adjust it directly.

“If the operator made a mis- take, it was a nightmare to trou- bleshoot,” Marion says, “and get the saw back up and running.”

To reduce downtime and increase productivity of the saw- ing operation, management decided to replace the saw’s aging controls with a new elec- trohydraulic motion controller, a model RMC75 E from Delta Computer Systems, Battle Ground, WA. Assisting Marion and the Catalina Cylinder crew with the retrofit was Greg Eschborn, president of Motion- Worx Corp., Upland, CA.

Motion-Control Tuning Wizardry

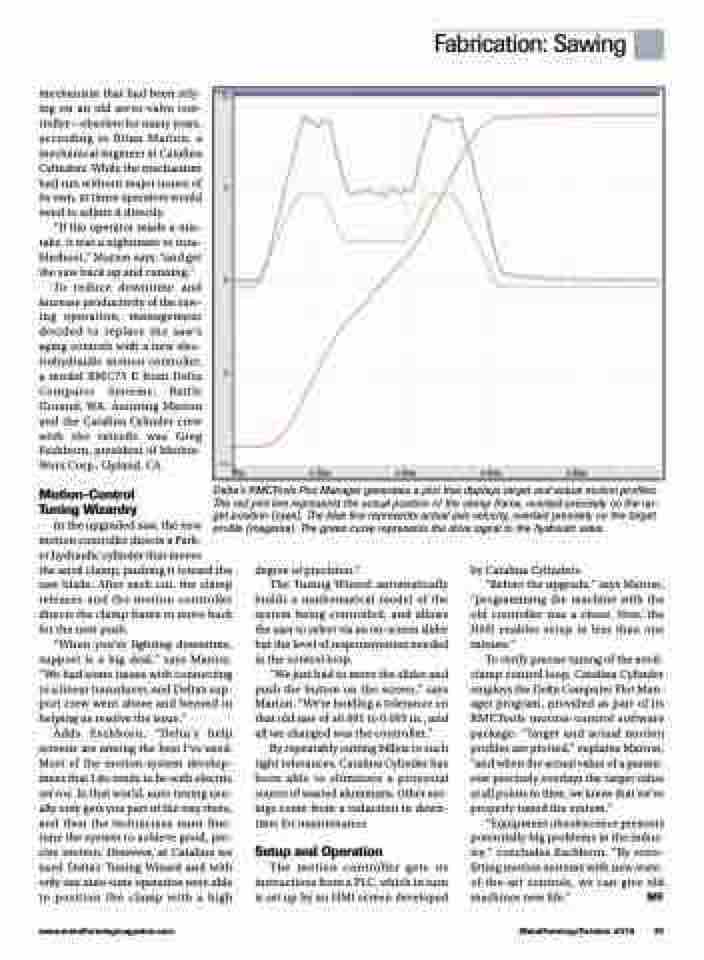

Delta’s RMCTools Plot Manager generates a plot that displays target and actual motion profiles. The red plot line represents the actual position of the clamp frame, overlaid precisely on the tar- get position (cyan). The blue line represents actual axis velocity, overlaid precisely on the target profile (magenta). The green curve represents the drive signal to the hydraulic valve.

In the upgraded saw, the new motion controller directs a Park-

er hydraulic cylinder that moves

the anvil clamp, pushing it toward the saw blade. After each cut, the clamp releases and the motion controller directs the clamp frame to move back for the next push.

“When you’re fighting downtime, support is a big deal,” says Marion. “We had some issues with connecting to a linear transducer, and Delta’s sup- port crew went above and beyond in helping us resolve the issue.”

Adds Eschborn, “Delta's help screens are among the best I’ve used. Most of the motion-system develop- ment that I do tends to be with electric servos. In that world, auto tuning usu- ally only gets you part of the way there, and then the technicians must fine- tune the system to achieve good, pre- cise motion. However, at Catalina we used Delta’s Tuning Wizard and with only one auto-tune operation were able to position the clamp with a high

degree of precision.”

The Tuning Wizard automatically

builds a mathematical model of the system being controlled, and allows the user to select via an on-screen slider bar the level of responsiveness needed in the control loop.

“We just had to move the slider and push the button on the screen,” says Marion. “We’re holding a tolerance on that old saw of ±0.001 to 0.003 in., and all we changed was the controller.”

By repeatably cutting billets to such tight tolerances, Catalina Cylinder has been able to eliminate a potential source of wasted aluminum. Other sav- ings come from a reduction in down- time for maintenance.

Setup and Operation

The motion controller gets its instructions from a PLC, which in turn is set up by an HMI screen developed

by Catalina Cylinders.

“Before the upgrade,” says Marion,

“programming the machine with the old controller was a chore. Now, the HMI enables setup in less than one minute.”

To verify precise tuning of the anvil- clamp control loop, Catalina Cylinder employs the Delta Computer Plot Man- ager program, provided as part of its RMCTools motion-control software package. “Target and actual motion profiles are plotted,” explains Marion, “and when the actual value of a param- eter precisely overlays the target value at all points in time, we know that we’ve properly tuned the system.”

“Equipment obsolescence presents potentially big problems in the indus- try,” concludes Eschborn. “By retro- fitting motion systems with new state- of-the-art controls, we can give old machines new life.” MF

www.metalformingmagazine.com

MetalForming/October 2019 87

Fabrication: Sawing