Page 82 - MetalForming-Oct-2018-issue

P. 82

FABRICATION

3D-Printed Press-Brake Tooling

Cuts Costs

...on machining and lead time for this South Carolina fabricator that decided to bring the technology inhouse.

Centerline Engineered Solutions, a Greenwood, SC, contract engi- neering and fabrication busi- ness, has deep roots, tracing back to 1918 when Alfred Proctor Aldrich founded Aldrich Machine Works. In 2004, the company merged with Swof- ford Engineering, and Centerline was born, bringing to bear a formidable array of machining, laser-cutting and bending capabilities to design, develop and deliver parts, as well as repair machinery.

Chances are that Aldrich did not foresee the advent of CNC machining and laser cutting, and most likely he would not know what to make of a newer Centerline capability, 3D print- ing. The fact is, businesses do not last for a century by doing the same old thing. As technology has presented itself as a viable option to forward the

80 MetalForming/October 2018

www.metalformingmagazine.com

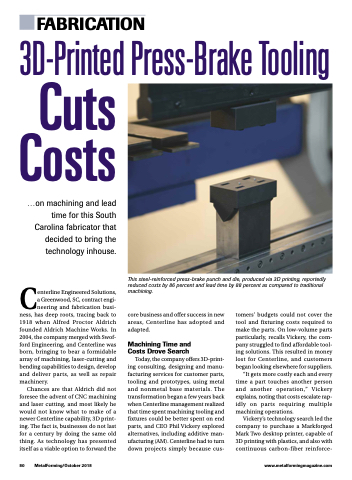

This steel-reinforced press-brake punch and die, produced via 3D printing, reportedly reduced costs by 86 percent and lead time by 88 percent as compared to traditional machining.

core business and offer success in new areas, Centerline has adopted and adapted.

Machining Time and Costs Drove Search

Today, the company offers 3D-print- ing consulting, designing and manu- facturing services for customer parts, tooling and prototypes, using metal and nonmetal base materials. The transformation began a few years back when Centerline management realized that time spent machining tooling and fixtures could be better spent on end parts, and CEO Phil Vickery explored alternatives, including additive man- ufacturing (AM). Centerline had to turn down projects simply because cus-

tomers’ budgets could not cover the tool and fixturing costs required to make the parts. On low-volume parts particularly, recalls Vickery, the com- pany struggled to find affordable tool- ing solutions. This resulted in money lost for Centerline, and customers began looking elsewhere for suppliers.

“It gets more costly each and every time a part touches another person and another operation,” Vickery explains, noting that costs escalate rap- idly on parts requiring multiple machining operations.

Vickery’s technology search led the company to purchase a Markforged Mark Two desktop printer, capable of 3D printing with plastics, and also with continuous carbon-fiber reinforce-