Page 81 - MetalForming-Oct-2018-issue

P. 81

Previews

Quick-Change Tooling

cut samples from both cutting processes available at FABTECH.

cutting, painting, sanding and other process professionals to program industrial robots without having to buy or learn complex CAD/CAM software.

Mate Precision Tooling Booth B7819

ProNest 2019 is a major-version update of Hypertherm’s CAD/CAM nesting software for automated cutting. This release contains more than a dozen new features and enhancements. The new version of Robot- master, v7, introduces a completely new architecture to the task-based robot-pro- gramming platform. It uses integrated CAD/CAM functionality that allows welding,

Mate has expanded its QCT product line to include QCT Metric, compatible with the company’s guides and canisters; AMX QCT for Amada air-blow systems;

In addition, Hypertherm will present its Powermax line of air-plasma-cutting and -gouging systems, along with its lineup of specialty torches and consumables, in the show’s Welding Hall, at Booth C12542.

www.metalformingmagazine.com

MetalForming/October 2018

79

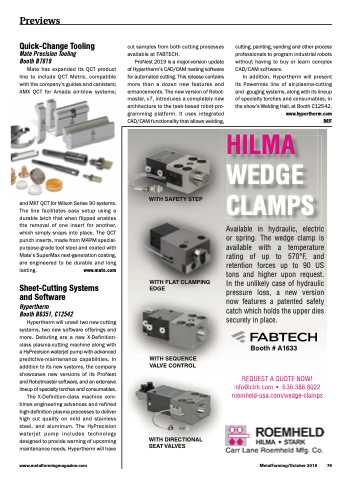

WITH DIRECTIONAL SEAT VALVES

MF

Available in hydraulic, electric or spring. The wedge clamp is available with a temperature rating of up to 570°F, and retention forces up to 90 US tons and higher upon request. In the unlikely case of hydraulic pressure loss, a new version now features a patented safety catch which holds the upper dies securely in place.

Booth # A1633

r

s

o

e

em

mh

h

e

e

l

l

d

d

-

-u

u

s

o

o

sa

a.

m

63

.

c

co

o

m

m/

/w

www.hypertherm.com

and MXT QCT for Wilson Series 90 systems. The line facilitates easy setup using a durable latch that when flipped enables the removal of one insert for another, which simply snaps into place. The QCT punch inserts, made from M4PM special- purpose-grade tool steel and coated with Mate’s SuperMax next-generation coating, are engineered to be durable and long lasting. www.mate.com

Sheet-Cutting Systems

and Software

WITH SAFETY STEP

HILMA

WEDGE

CLAMPS

Hypertherm

Booth B6351, C12542

WITH FLAT CLAMPING EDGE

WITH SEQUENCE VALVE CONTROL

Hypertherm will unveil two new cutting systems, two new software offerings and more. Debuting are a new X-Definition- class plasma-cutting machine along with a HyPrecision waterjet pump with advanced predictive-maintenance capabilities. In addition to its new systems, the company showcases new versions of its ProNest and Robotmaster software, and an extensive lineup of specialty torches and consumables.

R

RE

E

Q

Q

U

U

E

ES

S

T

T

A

AQ

m�

QU

U

O

O

w

T

T

36

E

E

N

6

e

ed

.

.3

d

N

3

g

ge

8

8

O

OW

e-

6

6

-

W

.

.

c

cl

8

8

la

!

!

i

�6

in

nf

fo

o

@

@c

cl

lr

r

h

h.

.

c

c

0

0

am

2

2

mp

2

The X-Definition-class machine com- bines engineering advances and refined high-definition plasma processes to deliver high cut quality on mild and stainless steel, and aluminum. The HyPrecision waterjet pump includes technology designed to provide warning of upcoming maintenance needs. Hypertherm will have

2

ro

p

s