Page 18 - MetalForming-Sep-2018-issue

P. 18

Stamper’s Success

IsTo Die For

Equipment and process changes ensure quicker die changes, increased press uptime and more at Northern Stamping, Inc.

BY JOE JANCSURAK, ASSOCIATE EDITOR

Throughout its 30-yr. history

as a Tier One automotive sup-

plier, Cleveland, OH-based

Northern Stamping, Inc. (NSI) has

evolved, adding along the way new

technologies such as automatic

transfer presses and robotic welding,

and always mindful of continuous

improvement. Lately, ramped-up

production demands from the likes

of General Motors, for whom NSI

stamps nearly 2.5 million tractor-

hitch parts (11 parts per assembly), as well as Chrysler, Cosma Magna and others, has driven NSI to transform itself like never before.

Over the past few years at its newly expanded 140,000- sq.-ft. stamping facility (NSI also has a nearby 85,000-sq.- ft. welding facility), the company has made these changes:

• Implemented a computerized maintenance-manage- ment system (CMMS) system from Woodbury, CT-based COGZ, to increase equipment uptime by tracking tasks for on-time completion and equipment histories.

• Maximized use of white boards to keep employees informed on the status of press tooling. Tools numbered in green represent those ready to run in the press, while red signifies tools that need repairs.

• Reorganized the warehouse to ensure efficient packing and flow of parts, allowing for more work by fewer employ- ees—from 10 to four—and freeing employees for other tasks.

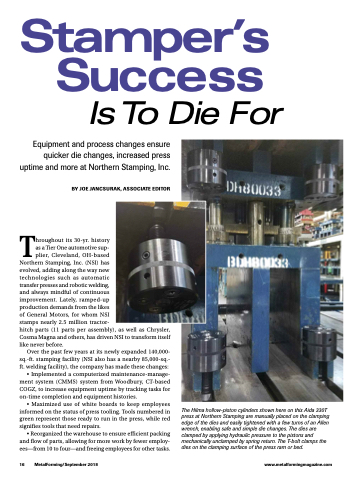

The Hilma hollow-piston cylinders shown here on this Aida 330T press at Northern Stamping are manually placed on the clamping edge of the dies and easily tightened with a few turns of an Allen wrench, enabling safe and simple die changes. The dies are clamped by applying hydraulic pressure to the pistons and mechanically unclamped by spring return. The T-bolt clamps the dies on the clamping surface of the press ram or bed.

16 MetalForming/September 2018

www.metalformingmagazine.com