Page 26 - MetalForming-Mar-2018-issue

P. 26

FABRICATION

ThreeThingsYou Need to Know to Prolong

Punch Life

Understanding these basic reasons for premature wear will enable you to get

the most from your tools.

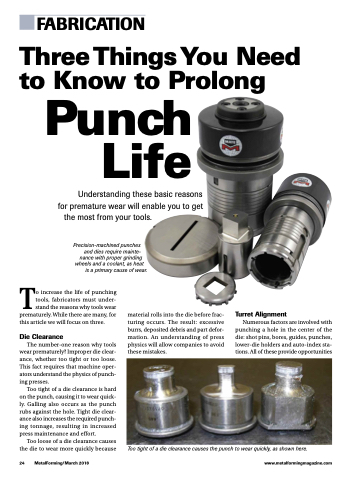

Precision-machined punches and dies require mainte- nance with proper grinding

wheels and a coolant, as heat is a primary cause of wear.

To increase the life of punching tools, fabricators must under- stand the reasons why tools wear prematurely. While there are many, for this article we will focus on three.

Die Clearance

The number-one reason why tools wear prematurely? Improper die clear- ance, whether too tight or too loose. This fact requires that machine oper- ators understand the physics of punch- ing presses.

Too tight of a die clearance is hard on the punch, causing it to wear quick- ly. Galling also occurs as the punch rubs against the hole. Tight die clear- ance also increases the required punch- ing tonnage, resulting in increased press maintenance and effort.

Too loose of a die clearance causes the die to wear more quickly because

material rolls into the die before frac- turing occurs. The result: excessive burrs, deposited debris and part defor- mation. An understanding of press physics will allow companies to avoid these mistakes.

Turret Alignment

Numerous factors are involved with punching a hole in the center of the die: shot pins, bores, guides, punches, lower-die holders and auto-index sta- tions. All of these provide opportunities

24 MetalForming/March 2018

www.metalformingmagazine.com

Too tight of a die clearance causes the punch to wear quickly, as shown here.