Page 48 - MetalForming-Jan-2018-issue

P. 48

The Science of Forming

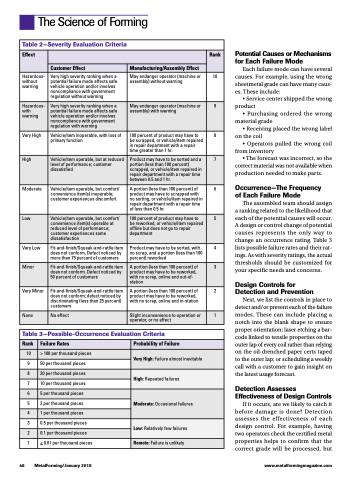

Table 2—Severity Evaluation Criteria

Effect

Rank

Customer Effect

Manufacturing/Assembly Effect

Hazardous- without warning

Very high severity ranking when a potential failure mode affects safe vehicle operation and/or involves noncompliance with government regulation without warning

May endanger operator (machine or assembly) without warning

10

Hazardous- with warning

Very high severity ranking when a potential failure mode affects safe vehicle operation and/or involves noncompliance with government regulation with warning

May endanger operator (machine or assembly) with warning

9

Very High

Vehicle/item inoperable, with loss of primary function

100 percent of product may have to be scrapped, or vehicle/item repaired in repair department with a repair time greater than 1 hr.

8

High

Vehicle/item operable, but at reduced level of performance; customer dissatisfied

Product may have to be sorted and a portion (less than 100 percent) scrapped, or vehicle/item repaired in repair department with a repair time between 0.5 and 1 hr.

7

Moderate

Vehicle/item operable, but comfort/ convenience item(s) inoperable; customer experiences discomfort

A portion (less than 100 percent) of product may have to scrapped with no sorting, or vehicle/item repaired in repair department with a repair time of less than 0.5 hr.

6

Low

Vehicle/item operable, but comfort/ convenience item(s) operable at reduced level of performance; customer experiences some dissatisfaction

100 percent of product may have to be reworked, or vehicle/item repaired offline but does not go to repair department

5

Very Low

Fit-and-finish/Squeak-and-rattle item does not conform. Defect noticed by more than 75 percent of customers

Product may have to be sorted, with no scrap, and a portion (less than 100 percent) reworked

4

Minor

Fit-and-finish/Squeak-and-rattle item does not conform. Defect noticed by 50 percent of customers

A portion (less than 100 percent) of product may have to be reworked, with no scrap, online and out-of- station

3

Very Minor

Fit-and-finish/Squeak-and-rattle item does not conform; defect noticed by discriminating (less than 25 percent) customers

A portion (less than 100 percent) of product may have to be reworked, with no scrap, online and in-station

2

None

No effect

Slight inconvenience to operation or operator, or no effect

1

Potential Causes or Mechanisms for Each Failure Mode

Each failure mode can have several causes. For example, using the wrong sheetmetal grade can have many caus- es. These include:

• Service center shipped the wrong product

• Purchasing ordered the wrong material grade

• Receiving placed the wrong label on the coil

• Operators pulled the wrong coil from inventory

• The forecast was incorrect, so the correct material was not available when production needed to make parts.

Occurrence—The Frequency of Each Failure Mode

The assembled team should assign a ranking related to the likelihood that each of the potential causes will occur. A design or control change of potential causes represents the only way to change an occurrence rating. Table 3 lists possible failure rates and their rat- ings. As with severity ratings, the actual thresholds should be customized for your specific needs and concerns.

Design Controls for Detection and Prevention

Next, we list the controls in place to detect and/or prevent each of the failure modes. These can include placing a notch into the blank shape to ensure proper orientation; laser etching a bar- code linked to tensile properties on the outer lap of every coil rather than relying on the oil-drenched paper certs taped to the outer lap; or scheduling a weekly call with a customer to gain insight on the latest usage forecast.

Detection Assesses Effectiveness of Design Controls

If it occurs, are we likely to catch it before damage is done? Detection assesses the effectiveness of each design control. For example, having two operators check the certified metal properties helps to confirm that the correct grade will be processed, but

Table 3—Possible-Occurrence Evaluation Criteria

Rank

Failure Rates

Probability of Failure

10

> 100 per thousand pieces

Very High: Failure almost inevitable

9

50 per thousand pieces

8

20 per thousand pieces

High: Repeated failures

7

10 per thousand pieces

6

5 per thousand pieces

Moderate: Occasional failures

5

2 per thousand pieces

4

1 per thousand pieces

3

0.5 per thousand pieces

Low: Relatively few failures

2

0.1 per thousand pieces

1

< 0.01 per thousand pieces

Remote: Failure is unlikely

46 MetalForming/January 2018

www.metalformingmagazine.com