Page 40 - MetalForming-Jan-2018-issue

P. 40

FABRICATION

Design for Manufacturing:

Guidelines

for Sheetmetal Fabrication

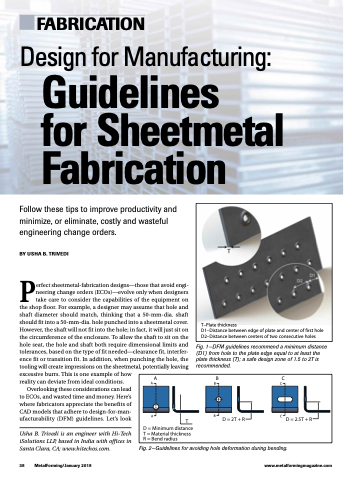

T–Plate thickness

D1–Distance between edge of plate and center of first hole D2–Distance between centers of two consecutive holes

Follow these tips to improve productivity and minimize, or eliminate, costly and wasteful engineering change orders.

BY USHA B. TRIVEDI

Perfect sheetmetal-fabrication designs—those that avoid engi- neering change orders (ECOs)—evolve only when designers take care to consider the capabilities of the equipment on the shop floor. For example, a designer may assume that hole and shaft diameter should match, thinking that a 50-mm-dia. shaft should fit into a 50-mm-dia. hole punched into a sheetmetal cover. However, the shaft will not fit into the hole; in fact, it will just sit on the circumference of the enclosure. To allow the shaft to sit on the hole seat, the hole and shaft both require dimensional limits and tolerances, based on the type of fit needed—clearance fit, interfer- ence fit or transition fit. In addition, when punching the hole, the tooling will create impressions on the sheetmetal, potentially leaving excessive burrs. This is one example of how

Fig. 1—DFM guidelines recommend a minimum distance (D1) from hole to the plate edge equal to at least the plate thickness (T); a safe design zone of 1.5 to 2T is recommended.

ABC

ABC

T

D = Minimum distance T = Material thickness R = Bend radius

D = 2.5T + R

A

B

C

D = 2T + R

reality can deviate from ideal conditions. Overlooking these considerations can lead to ECOs, and wasted time and money. Here’s where fabricators appreciate the benefits of CAD models that adhere to design-for-man- ufacturability (DFM) guidelines. Let’s look

Usha B. Trivedi is an engineer with Hi-Tech iSolutions LLP, based in India with offices in Santa Clara, CA; www.hitechos.com.

Fig. 2—Guidelines for avoiding hole deformation during bending.

38 MetalForming/January 2018

www.metalformingmagazine.com