Page 76 - MetalForming October 2017

P. 76

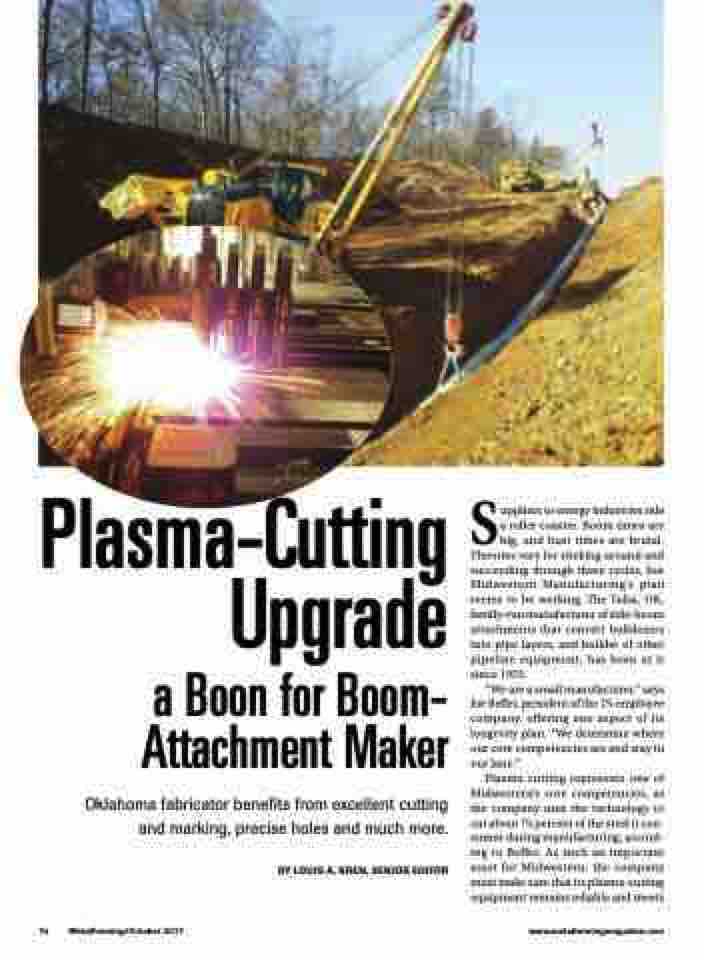

Plasma-Cutting Suppliers to energy industries ride a roller coaster. Boom times are big, and bust times are brutal. Theories vary for sticking around and succeeding through these cycles, but Midwestern Manufacturing’s plan seems to be working. The Tulsa, OK, family-run manufacturer of side-boom attachments that convert bulldozers into pipe layers, and builder of other pipeline equipment, has been at it

Upgrade

a Boon for Boom- Attachment Maker

Oklahoma fabricator benefits from excellent cutting and marking, precise holes and much more.

BY LOUIS A. KREN, SENIOR EDITOR

since 1953.

“We are a small manufacturer,” says

Joe Beffer, president of the 75-employee company, offering one aspect of its longevity plan. “We determine where our core competencies are and stay in our lane.”

Plasma cutting represents one of Midwestern’s core competencies, as the company uses the technology to cut about 75 percent of the steel it con- sumes during manufacturing, accord- ing to Beffer. As such an important asset for Midwestern, the company must make sure that its plasma-cutting equipment remains reliable and meets

74 MetalForming/October 2017

www.metalformingmagazine.com