Page 28 - MetalForming June 2017

P. 28

Advanced Functions of Arc-Welding

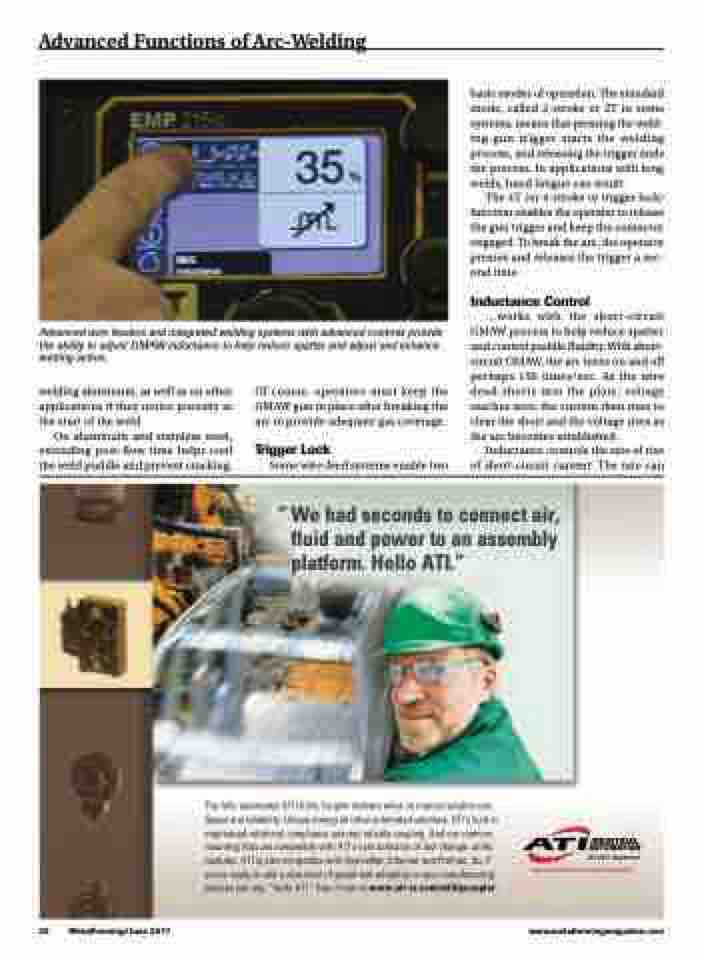

Advanced wire feeders and integrated welding systems with advanced controls provide the ability to adjust GMAW inductance to help reduce spatter and adjust and enhance wetting action.

basic modes of operation. The standard mode, called 2-stroke or 2T in some systems, means that pressing the weld- ing-gun trigger starts the welding process, and releasing the trigger ends the process. In applications with long welds, hand fatigue can result.

The 4T (or 4-stroke or trigger lock) function enables the operator to release the gun trigger and keep the contactor engaged. To break the arc, the operator presses and releases the trigger a sec- ond time.

Inductance Control

...works with the short-circuit GMAW process to help reduce spatter and control puddle fluidity. With short- circuit GMAW, the arc turns on and off perhaps 150 times/sec. As the wire dead-shorts into the plate, voltage reaches zero; the current then rises to clear the short and the voltage rises as the arc becomes established.

Inductance controls the rate of rise of short-circuit current. The rate can

welding aluminum, as well as on other applications if they notice porosity at the start of the weld.

On aluminum and stainless steel, extending post-flow time helps cool the weld puddle and prevent cracking.

Of course, operators must keep the GMAW gun in place after breaking the arc to provide adequate gas coverage.

Trigger Lock

Some wire-feed systems enable two

“ We had seconds to connect air, fluid and power to an assembly platform. Hello ATI.”

The fully automated ATI Utility Coupler delivers what no manual solution can. Speed and reliability. Unique among all other automated solutions, ATI’s built-in engineered rotational compliance ensures reliable coupling. And our common mounting flats are compatible with ATI’s vast selection of tool changer utility modules. ATI is also compatible with DeviceNet, Ethernet and Profinet. So, if you’re ready to add a new level of speed and reliability to your manufacturing process just say, “Hello ATI.” See it now at www.ati-ia.com/utilitycoupler.

26 MetalForming/June 2017

www.metalformingmagazine.com