Page 24 - MetalForming June 2017

P. 24

Success in Medical Stamping

...depends on high-speed precision presses backed by

state-of-the-art support equipment. Blending that with

advanced knowledge of customer needs can win

coveted medical work.

BY TIM LYNCH

With the market for implantable medical devices growing rapidly, manufacturers are developing amazing new therapeu-

tic technologies for orthopedic, cardiovascular and other conditions. Metal-stamping firms must

be equipped to support that innovation and assist OEMs in speeding time to market for new devices.

“Metal stampings for implantable devices, surgical devices and drug delivery devices, all must meet critical FDA Class III regulations and be manufactured in a process that controls for risk and quality,” observes Steve Fischer, president of Peterson Enterprises, which represents a variety of manu- facturers, including Kenmode. “With the rapid innovation by manufacturers in developing new endoscopic and laparo- scopic surgical tools, and improved implantable devices such as pacemakers, defibrillators, and neuro-stimulators, metal stampers have to be just as quick to innovate their practices. Because development of metal-stamping tooling

Tim Lynch is vice president of sales and marketing for Ken- mode Precision Metal Stamping, Algonquin, IL, tel. 847/658- 5041, www.kenmode.com.

is inherently a time-consuming process, the premier stamp- ing firms are finding new ways to speed up part design, tooling and production to accommodate the emerging need.”

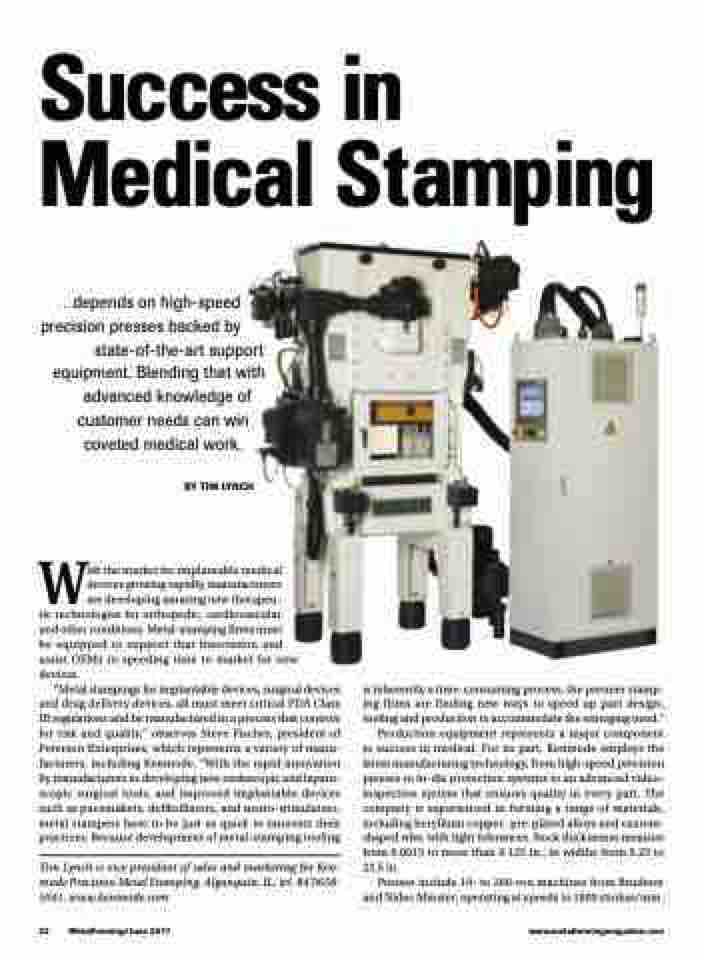

Production equipment represents a major component to success in medical. For its part, Kenmode employs the latest manufacturing technology, from high-speed precision presses to in-die protection systems to an advanced video- inspection system that ensures quality in every part. The company is experienced in forming a range of materials, including beryllium copper, pre-plated alloys and custom- shaped wire, with tight tolerances. Stock thicknesses measure from 0.0015 to more than 0.125 in., in widths from 0.25 to 23.5 in.

Presses include 10- to 200-ton machines from Bruderer and Nidec Minster, operating at speeds to 1800 strokes/min.

22 MetalForming/June 2017

www.metalformingmagazine.com