Page 51 - MetalForming April 2017

P. 51

The Science of Forming

ABCDEF

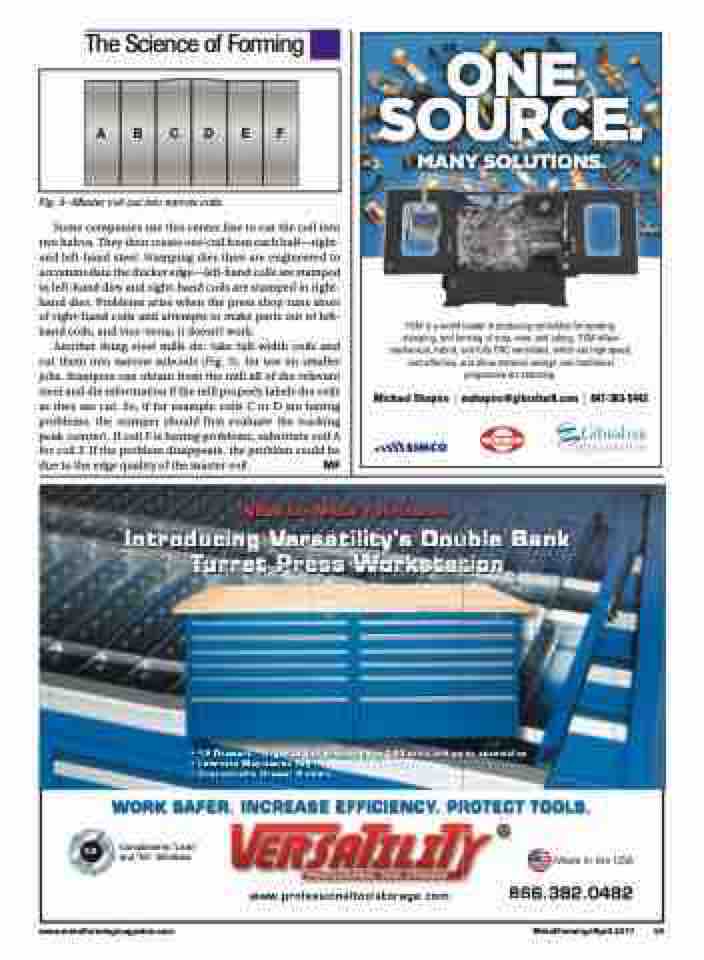

Fig. 3—Master coil cut into narrow coils.

Some companies use this center line to cut the coil into two halves. They then create one coil from each half—right- and left-hand steel. Stamping dies then are engineered to accommodate the thicker edge—left-hand coils are stamped in left-hand dies and right-hand coils are stamped in right- hand dies. Problems arise when the press shop runs short of right-hand coils and attempts to make parts out of left- hand coils, and vice-versa; it doesn’t work.

Another thing steel mills do: take full-width coils and cut them into narrow subcoils (Fig. 3), for use on smaller jobs. Stampers can obtain from the mill all of the relevant steel and die information if the mill properly labels the coils as they are cut. So, if for example coils C or D are having problems, the stamper should first evaluate the tracking peak (center). If coil F is having problems, substitute coil A for coil F. If the problem disappears, the problem could be due to the edge quality of the master coil. MF

NEW f

YSM is a world leader in producing vertislides for bending, stamping, and forming of strip, wire, and tubing. YSM offers mechanical, hybrid, and fully CNC vertislides, which are high speed, cost effective, and allow material savings over traditional progressive die stamping.

Michael Shapiro | mshapiro@gibraltar8.com | 847-383-5442

t

et

t

tP

P

P

o

r

r Me

al F

re

e

e

es

ss

sW

Wo

ab

r

or

r

ic

at

’s Double Bank

k

k

ks

or

st

s

I

ntroducing V

ersatility

e

Tu

ur

rr

re

ta

at

ti

i

io

o

n

n

• 12 Dr

a

w

e

r

s–O

r

gani

ze and p

r

ot

e

r

c

t up t

o 750 t

oo

ls and guide asse

mb

ECT T

lie

s

• L

•C

WORK SA

Compliments “Lean” and “5S” Initiatives

a

am

mi

i

n

na

at

t

e

eM

Ma

ap

us

FER INCREA

t

o

miz

ab

p

l

le D

le

e

r

w

w

o

o

aw

e

o

o

d

dT

T

r Di

s

o

op

p

vi

ide

SE EFFICIENCY PROT

O

S

OLS.

5S

w

866.382.0482 m8

ww

w

w

w.pr

ro

o

f

fe

e

s

ss

si

io

on

na

al

l

t

t

o

oo

ol

ls

st

t

o

or

ra

ag

g

e

e.co

om

www.metalformingmagazine.com

MetalForming/April 2017 49