Page 26 - MetalForming April 2017

P. 26

Dune-Buggy Maker Cruises to

Laser-Shop Success

Business for this So-Cal sheetmetal job shop has increased 35 percent, while profit margins are up and production time

is down, thanks in part to a new

fiber-laser cutting machine.

Prior to opening his Southern- California job shop in 2001, Larry Rosevear honed his sheetmet- al-fabrication skills by building dune buggies...a lot of dune buggies.

“My company was selling 100 bug- gies per year,” reflects Rosevear. “I pur- chased my first laser-cutting machine in 2000, and appreciated how much faster it could produce parts compared to my plasma-cutting machine.”

So fast, in fact, that Rosevear says each day he could finish all of the cut- ting work needed to build his buggies in just 2 hr., leaving the laser-cutting machine sitting idle for 6 hr. So, he began taking on odd jobs for the cut- ting machine.

“Soon I began cutting parts for other people, and we began to receive more and more orders,” he says.

The business grew so quickly that the company, in 2001, evolved into a 100-percent sheetmetal-fabrication job shop—Laser Innovations. The fledgling company launched operations with

the laser-cutting machine, as well as a waterjet machine and a press brake.

“The job-shop business proved eas- ier to predict than the dune-buggy business,” explains Rosevear. “My early clientele were my customers who had purchased dune buggies—they saw the quality of the laser. We were getting business through word of mouth, and soon I was even building parts for my previous dune-buggy competitors.”

Cruising to Success

Today, the company occupies two 8700-sq.-ft. buildings in Anaheim, CA, with an equipment list that includes multiple CO2 laser- and waterjet-cut- ting machines, as well as forming and welding equipment that support cus- tomers in the medical, display, military,

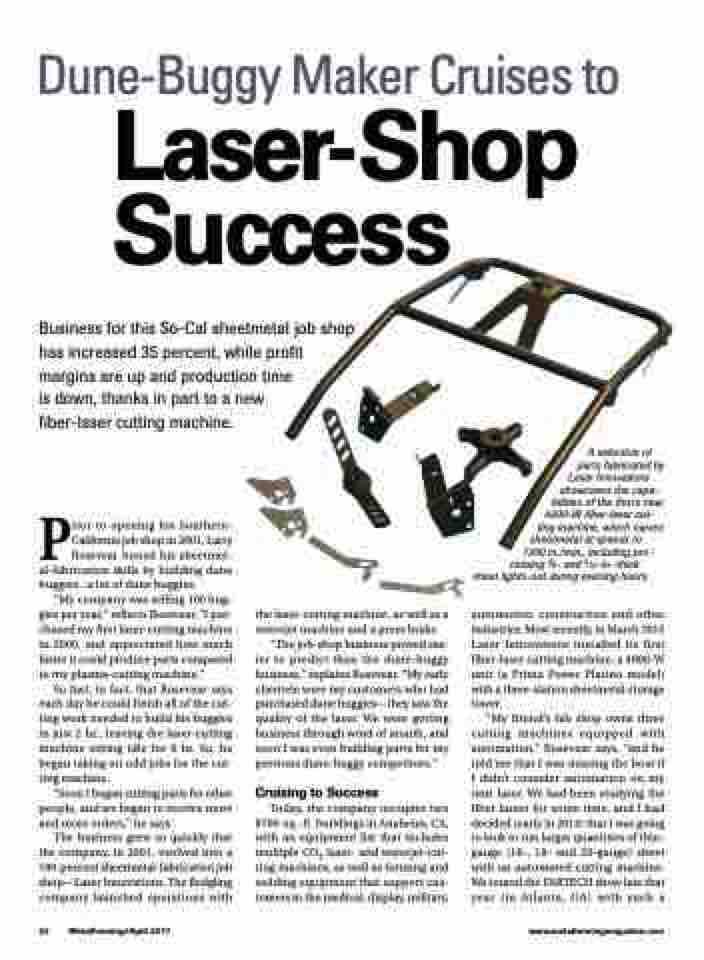

A selection of parts fabricated by

Laser Innovations showcases the capa- bilities of the firm’s new

4000-W fiber-laser cut- ting machine, which carves

sheetmetal at speeds to 1200 in./min., including pro-

cessing 3⁄8- and 5⁄16-in.-thick sheet lights-out during evening hours.

automotive, construction and other industries. Most recently, in March 2015 Laser Innovations installed its first fiber-laser cutting machine, a 4000-W unit (a Prima Power Platino model) with a three-station sheetmetal-storage tower.

“My friend’s fab shop owns three cutting machines equipped with automation,” Rosevear says, “and he told me that I was missing the boat if I didn’t consider automation on my next laser. We had been studying the fiber lasers for some time, and I had decided (early in 2014) that I was going to look to run larger quantities of thin- gauge (16-, 18- and 20-gauge) sheet with an automated cutting machine. We toured the FABTECH show late that year (in Atlanta, GA) with such a

24 MetalForming/April 2017

www.metalformingmagazine.com