Page 18 - MetalForming November 2016

P. 18

Do You Place a Dollar Value on Downtime?

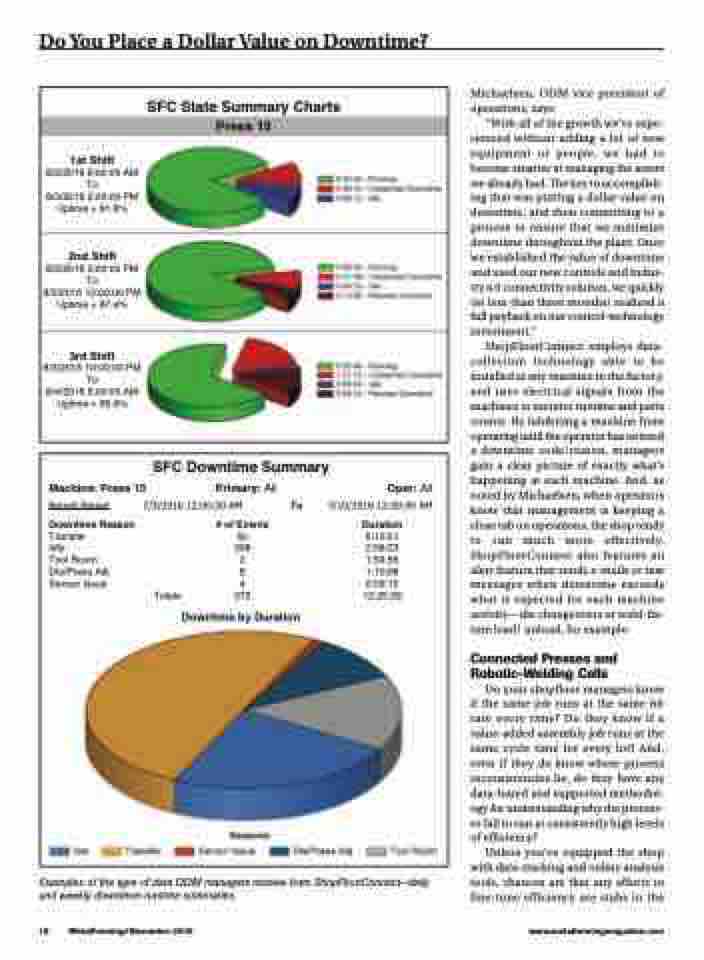

SFC State Summary Charts

Press 15

1st Shift

8/3/2016 6:00:00 AM To 8/3/2016 2:00:00 PM Uptime = 81.8%

2nd Shift

8/3/2016 2:00:00 PM To

8/3/2016 10:00:00 PM Uptime = 87.4%

3rd Shift

8/3/2016 10:00:00 PM To

8/4/2016 6:00:00 AM Uptime = 68.9%

SFC Downtime Summary Machine: Press 15 Primary: All

Report Period

Downtime Reason

Transfer

Idle

Tool Room Die/Press Adj Sensor Issue

7/3/2016 12:00:00 AM

# of Events

50 208 2 8 4

To

Oper: All 7/10/2016 12:00:00 AM

Duration

6:12:51 2:58:23 1:54:55 1:10:08 0:09:12

Totals 272 12:25:29

Downtime by Duration

Examples of the type of data ODM managers receive from ShopFloorConnect—daily and weekly downtime-runtime summaries.

Michaelsen, ODM vice president of operations, says:

“With all of the growth we’ve expe- rienced without adding a lot of new equipment or people, we had to become smarter at managing the assets we already had. The key to accomplish- ing that was putting a dollar value on downtime, and then committing to a process to ensure that we minimize downtime throughout the plant. Once we established the value of downtime and used our new controls and Indus- try 4.0 connectivity solution, we quickly (in less than three months) realized a full payback on our control-technology investment.”

ShopFloorConnect employs data- collection technology able to be installed at any machine in the factory, and uses electrical signals from the machines to monitor runtime and parts counts. By inhibiting a machine from operating until the operator has entered a downtime code/reason, managers gain a clear picture of exactly what’s happening at each machine. And, as noted by Michaelsen, when operators know that management is keeping a close tab on operations, the shop tends to run much more effectively. ShopFloorConnect also features an alert feature that sends e-mails or text messages when downtime exceeds what is expected for each machine activity—die changeovers or weld-fix- ture load/ unload, for example.

Connected Presses and Robotic-Welding Cells

Do your shopfloor managers know if the same job runs at the same hit rate every time? Do they know if a value-added assembly job runs at the same cycle time for every lot? And, even if they do know where process inconsistencies lie, do they have any data-based and supported methodol- ogy for understanding why the process- es fail to run at consistently high levels of efficiency?

Unless you’ve equipped the shop with data-tracking and online analysis tools, chances are that any efforts to fine-tune efficiency are stabs in the

16 MetalForming/November 2016

www.metalformingmagazine.com