Page 26 - MetalForming September 2016

P. 26

Automotive Outlook

Recently, Harbour Results, in conjunc- tion with PMA, introduced the Strate- gic Assessment Program (SAP), designed to help members improve operational efficiency. Through this program, die-industry improvements will be tracked as well as trends around challenges and opportunities across all shops.

The tool-and-die industry is cyclical by nature, and to help level out the

effects of business peaks and valleys, companies must develop strategic sales processes. A successful sales process has seven steps (Fig. 2):

1) Company strategy 2) Target markets

3) Sales planning

4) Demand planning 5) Pricing and quoting 6) Data analysis

7) Feedback

Today, very rarely do shops formally utilize all seven of these steps. A good spot to start is with data the company already collects. To develop a process, leadership must understand the cur- rent state of the business. For example, an analysis of a company’s current request for quote (RFQ) hit-rate data across customers, jobs, type of work, etc., can provide insights that help establish a sound sales strategy.

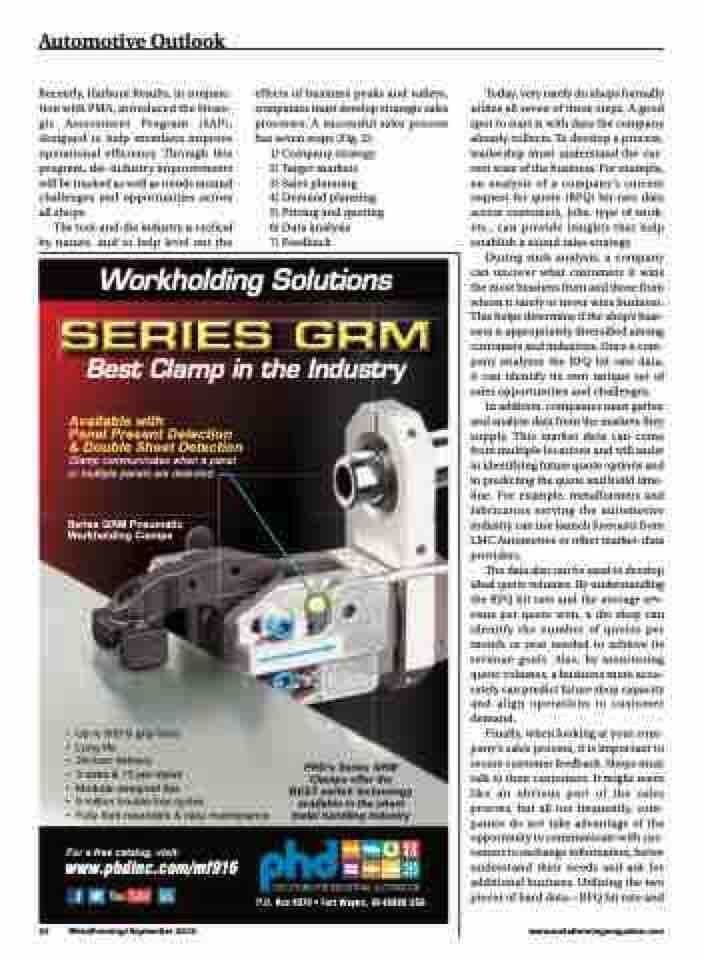

Workholding Solutions

During such analysis, a company can uncover what customers it wins the most business from and those from whom it rarely or never wins business. This helps determine if the shop’s busi- ness is appropriately diversified among customers and industries. Once a com- pany analyzes the RFQ hit-rate data, it can identify its own unique set of sales opportunities and challenges.

In addition, companies must gather and analyze data from the markets they supply. This market data can come from multiple locations and will assist in identifying future quote options and in predicting the quote and build time- line. For example, metalformers and fabricators serving the automotive industry can use launch forecasts from LMC Automotive or other market-data providers.

The data also can be used to develop ideal quote volumes. By understanding the RFQ hit rate and the average rev- enue per quote won, a die shop can identify the number of quotes per month or year needed to achieve its revenue goals. Also, by monitoring quote volumes, a business more accu- rately can predict future shop capacity and align operations to customer demand.

Finally, when looking at your com- pany’s sales process, it is important to secure customer feedback. Shops must talk to their customers. It might seem like an obvious part of the sales process, but all too frequently, com- panies do not take advantage of the opportunity to communicate with cus- tomers to exchange information, better understand their needs and ask for additional business. Utilizing the two pieces of hard data—RFQ hit rate and

S

SE

ER

RI

I

E

E

S

SG

Best Clamp in the Industry

Available with

Panel Present Detection & Double Sheet Detection Clamp communicates when a panel or multiple panels are detected.

Series GRM Pneumatic Workholding Clamps

GR

RM

M

� �� �� ��� �� ���� �����

� ���� ����

� ������� ��������

� � ����� � �� ��� ������

� ���������������� ����

� � ������� ������������ ������

� ����� ��������������� � ���� �����������

PHD’s Series GRM Clamps offer the BEST switch technology available in the sheet metal handling industry

For a free catalog, visit:

www.phdinc.com/mf916

���� ��� ���� � ���� ������ �� ����� ���

24

MetalForming/September 2016

www.metalformingmagazine.com