Page 16 - MetalForming July 2016

P. 16

Tech Update

our cutting table is down from 10 to 20 min. to 1 to 2 min., a huge leap in pro- ductivity for our process.”

Press-Brake Tooling Enables Bending to 40 Deg. Without Deformed Holes, Marks

The new system also features a custom slanted tank with a blow-down option, a feature that Yoxo also had retrofitted to its first waterjet machine. The slanted tank makes it easier to clean out pulp debris, while the blow-down system helps hold material in place during the cutting process.

Bend delicate and standard materials to 40 deg with minimal to no marking using CleanBend press-brake tooling dies from Mate Precision Tooling, Anoka, MN. Using rotating supports within the tooling, the new tooling enables precise bending for the high-quality sheetmetal forming, according to company officials.

“This has drastically cut down on tank cleaning and increased the quality of our cuts by almost completely eliminating splash-back onto our products,” Burns says.

CleanBend tooling is designed for a range of applications such as bending short flanges; bending a flange to a diag- onal sharp or across existing holes; and bending delicate and highly polished mate- rials including painted, coated and plas- tic-covered.

According to Burns, the decision to add a second waterjet machine “was a no- brainer. We needed the production capacity, redundancy and efficiency. The investment in another waterjet has more than doubled our production output quickly, with an increase in quality.”

Jet Edge, Inc.: www.jetedge.com

The tooling is made from high-speed

tool steel and is available for press brakes

configured with European Precision, Wila,

Trumpf and American-style systems in a range of sizes, from 8 to 30 mm.

See the CleanBend in operation at www.youtube.com/watch?v=wANZFc3HTOs.

Mate Precision Tooling: www.mate.com

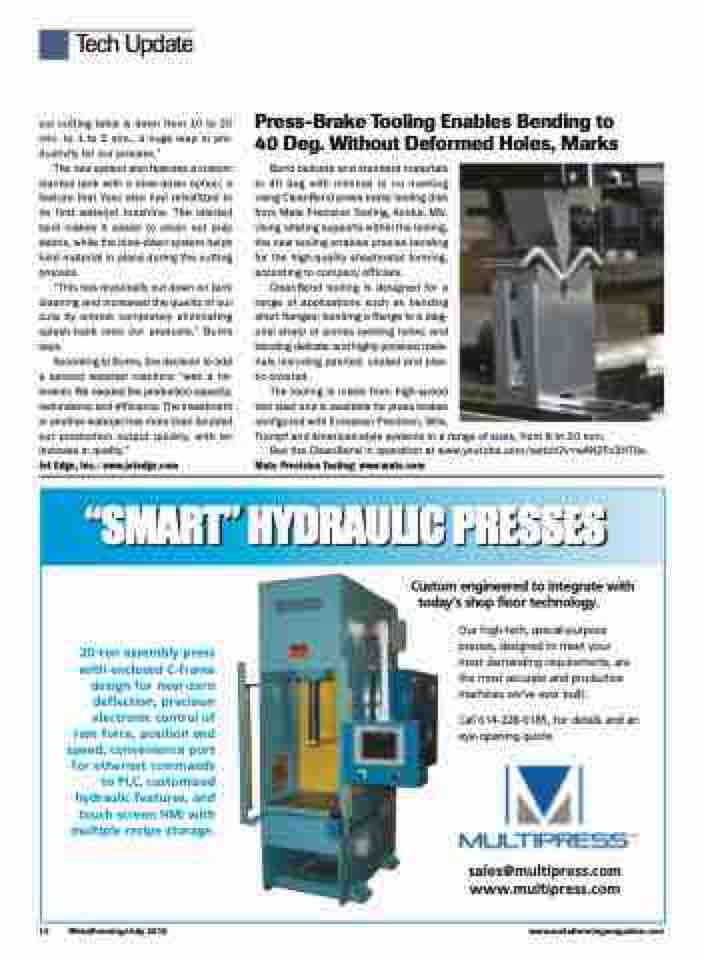

“SMART” HYDRAULIC PRESSES

“SMART” HYDRAULIC PRESSES

20-ton assembly press with enclosed C-frame design for near-zero deflection, precision electronic control of ram force, position and speed, convenience port for ethernet commands to PLC, customized hydraulic features, and touch screen HMI with multiple recipe storage.

Custom engineered to integrate with today’s shop floor technology.

Our high-tech, special-purpose presses, designed to meet your most demanding requirements, are the most accurate and productive machines we’ve ever built.

Call 614-228-0185, for details and an eye-opening quote.

TM

sales@multipress.com www.multipress.com

14 MetalForming/July 2016

www.metalformingmagazine.com