Page 56 - MetalForming March 2016

P. 56

Tooling by Design

By Peter Ulintz

Blankholder Forces in Asymmetrical Cup Drawing

Punch

Blankholder

Blankholder

Die entry Unsupported Die entry radius “loose” radius

material

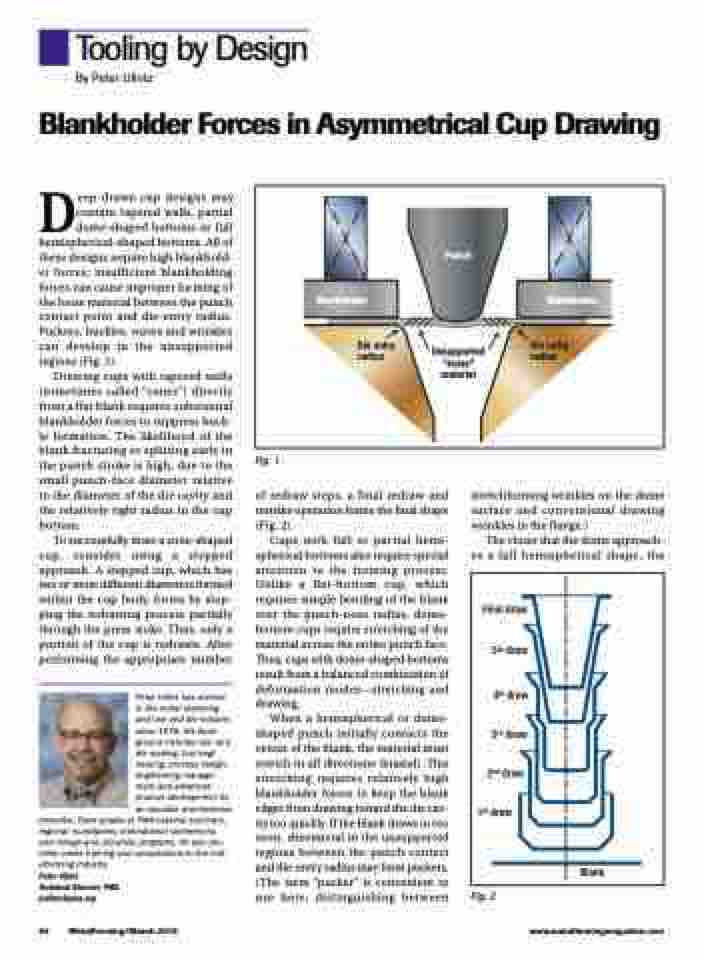

Deep-drawn cup designs may contain tapered walls, partial dome-shaped bottoms or full hemispherical-shaped bottoms. All of these designs require high blankhold- er forces; insufficient blankholding forces can cause improper forming of the loose material between the punch contact point and die-entry radius. Puckers, buckles, waves and wrinkles can develop in the unsupported regions (Fig. 1).

Drawing cups with tapered walls (sometimes called “cones”) directly from a flat blank requires substantial blankholder forces to suppress buck- le formation. The likelihood of the blank fracturing or splitting early in the punch stroke is high, due to the small punch-face diameter relative to the diameter of the die cavity and the relatively tight radius in the cup bottom.

To successfully draw a cone-shaped cup, consider using a stepped approach. A stepped cup, which has two or more different diameters formed within the cup body, forms by stop- ping the redrawing process partially through the press stoke. Thus, only a portion of the cup is redrawn. After performing the appropriate number

Peter Ulintz has worked in the metal stamping and tool and die industry since 1978. His back- ground includes tool and die making, tool engi- neering, process design, engineering manage- ment and advanced product development. As an educator and technical

presenter, Peter speaks at PMA national seminars, regional roundtables, international conferences, and college and university programs. He also pro- vides onsite training and consultations to the met- alforming industry.

Peter Ulintz

Technical Director, PMA pulintz@pma.org

Fig. 1

of redraw steps, a final redraw and restrike operation forms the final shape (Fig. 2).

Cups with full or partial hemi- spherical bottoms also require special attention to the forming process. Unlike a flat-bottom cup, which requires simple bending of the blank over the punch-nose radius, dome- bottom cups require stretching of the material across the entire punch face. Thus, cups with dome-shaped bottoms result from a balanced combination of deformation modes—stretching and drawing.

When a hemispherical or dome- shaped punch initially contacts the center of the blank, the material must stretch in all directions (biaxial). This stretching requires relatively high blankholder forces to keep the blank edges from drawing toward the die cav- ity too quickly. If the blank draws in too soon, sheetmetal in the unsupported regions between the punch contact and die-entry radius may form puckers. (The term “pucker” is convenient to use here, distinguishing between

stretchforming wrinkles on the dome surface and conventional drawing wrinkles in the flange.)

The closer that the dome approach- es a full hemispherical shape, the

Final draw

5th draw

4th draw 3rd draw

2nd draw 1st draw

Blank

54 MetalForming/March 2016

www.metalformingmagazine.com

Fig. 2