Page 34 - MetalForming February 2016

P. 34

Sky’s the Limit for

Sky’s the Limit for

California Waterjet Shop

California Waterjet Shop

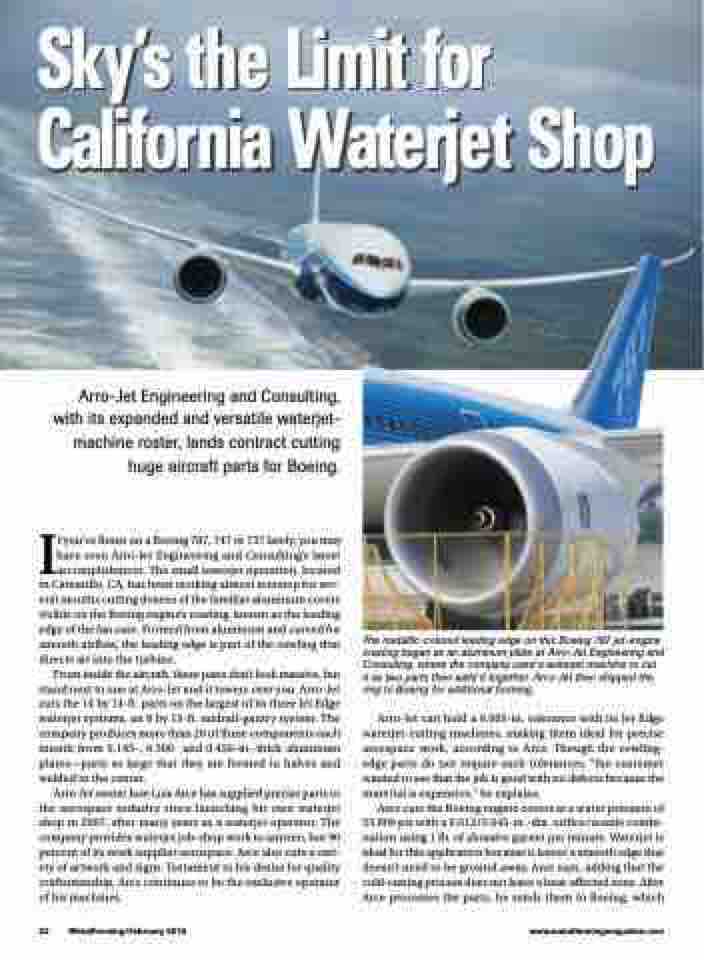

Arro-Jet Engineering and Consulting, with its expanded and versatile waterjet- machine roster, lands contract cutting huge aircraft parts for Boeing.

If you’ve flown on a Boeing 787, 747 or 737 lately, you may have seen Arro-Jet Engineering and Consulting’s latest accomplishment. The small waterjet operation, located in Camarillo, CA, has been working almost nonstop for sev- eral months cutting dozens of the familiar aluminum covers visible on the Boeing engine’s cowling, known as the leading edge of the fan case. Formed from aluminum and curved for smooth airflow, the leading edge is part of the cowling that directs air into the turbine.

From inside the aircraft, these parts don’t look massive, but stand next to one at Arro-Jet and it towers over you. Arro-Jet cuts the 14 by 14-ft. parts on the largest of its three Jet Edge waterjet systems, an 8 by 13-ft. midrail-gantry system. The company produces more than 20 of these components each month from 0.145-, 0.300- and 0.450-in.-thick aluminum plates—parts so large that they are formed in halves and welded in the center.

Arro-Jet owner Jose Luis Arce has supplied precise parts to the aerospace industry since launching his own waterjet shop in 2007, after many years as a waterjet operator. The company provides waterjet job-shop work to anyone, but 90 percent of its work supplies aerospace. Arce also cuts a vari- ety of artwork and signs. Testament to his desire for quality craftsmanship, Arce continues to be the exclusive operator of his machines.

The metallic-colored leading edge on this Boeing 787 jet-engine cowling began as an aluminum plate at Arro-Jet Engineering and Consulting, where the company used a waterjet machine to cut it as two parts then weld it together. Arro-Jet then shipped the ring to Boeing for additional forming.

Arro-Jet can hold a 0.005-in. tolerance with its Jet Edge waterjet-cutting machines, making them ideal for precise aerospace work, according to Arce. Though the cowling- edge parts do not require such tolerances, “the customer wanted to see that the job is good with no defects because the material is expensive,” he explains.

Arce cuts the Boeing engine covers at a water pressure of 55,000 psi with a 0.012/0.045-in.-dia. orifice/nozzle combi- nation using 1 lb. of abrasive garnet per minute. Waterjet is ideal for this application because it leaves a smooth edge that doesn’t need to be ground away, Arce says, adding that the cold-cutting process does not leave a heat-affected zone. After Arce processes the parts, he sends them to Boeing, which

32 MetalForming/February 2016

www.metalformingmagazine.com