Page 39 - MetalForming August 2015

P. 39

more accurate predictions of future requirements.

Improve communications—Post- ponement manufacturing requires increased communication between customers, suppliers and partners. Often, manufacturers will turn to part- ners to complete the product or per- form specialized finishing tasks such as adding a name, or picking and packing orders. This requires real-time visibili- ty between multiple locations and sys- tems. Advanced enterprise solutions meet that need by strengthening com- munications within the company and among partners, including the use of mobile and social tools. Collaborative tools also play an important role in coordinating multiple resources.

Manage production at a more gran- ular level—Advanced enterprise solu- tions offer new capabilities to manage sourcing, production and inventory at the component and serial-number level. This ability to monitor key processes at a more granular level allows the manufacturer to efficiently manage individualized production and assembly requirements. Combined with tools for improved visibility, the manufacturer can allocate components from one product to another when there is capability and a need.

Improve demand forecasting—New levels of supply-chain-management capabilities, working in concert with advanced analytics and BI capabilities, help companies to better forecast demand, predict specific future requirements and manage their supply chains and production.

Better manage bill-of-material (BOM) complexity—Postponement manufacturing takes BOM require- ments to a much higher level. With postponement manufacturing, just establishing what you need to build a product is not adequate. Your compa- ny also must manage BOMs through- out the product-manufacturing process. Modern software solutions can manage a vast increase in the num- ber of product components that must be tracked and the efficiency with which they’re monitored. MF

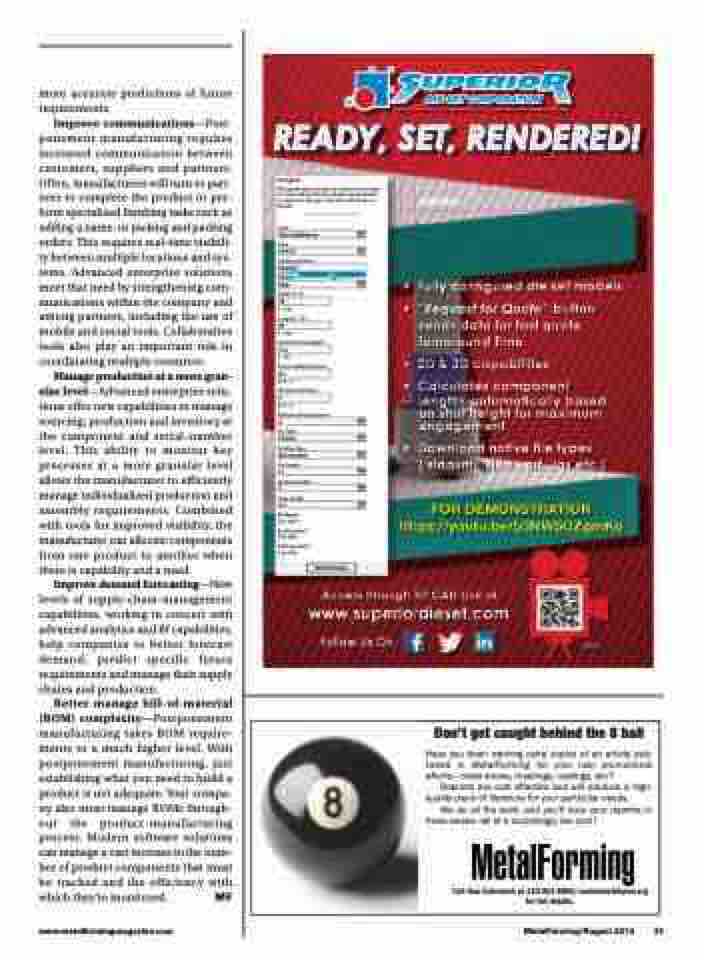

READY, SET, RENDERED!

www.metalformingmagazine.com

MetalForming/August 2015 37

Confifigure

Change the options below to customize the model for downloading. Click the Update Preview button to apply your changes to the 3D or 2D viewer on the left.

Type:

Type A Ball Bearing

Style: Style 75

Ball Bearing Type: Standard Maxicage Material:

1020

Width (F - B):

3B

4 - 150

Length (L - R): 64

4 - 150

Minimum Shut Height: 11.5

3 - 30

Punch Holder Thickness: 2.5

0.75 - 6

Die Shoe Thickness:

3

0.75 - 6

Diameter of Components 2

Pin Type:

Straight

Bushing Type: Demountable

Pin Length:

11

Bushing Length:

� ����� ��������� ��� ��� ������ � “Request for Quote� ������

����� ���� ��� ���� ����� ���������� ����

� �� � �� ������������

� ���������� ���������

������� ������������� ����� �� ���� ������ ��� ������� ����������

� �������� ������ ��� ����� ��������� ������ ����� ���� �����

FOR DEMONSTRATION https://youtu.be/b3NW5OZgmKo

5

Cage Length:

4.5

Pin Part #:

331-1644 Bushing Part #:

336-1650

Ball Cage Part #: 335-1618

Update Preview

������ ������� �� ��� ���� �� ����������������������

������ �� ��

video

Don’t get caught behind the 8 ball

Have you been wanting extra copies of an article pub- lished in MetalForming for your own promotional efforts— trade shows, meetings, mailings, etc ?

Reprints are cost effective and will produce a high- quality piece of literature for your particular needs.

We do all the work, and you’ll have your reprints in three weeks—all at a surprisingly low cost !

Call Sue Cubranich at 216-901-8800/scubranich@pma.org for full details.