Page 40 - MetalForming July 2015

P. 40

1

n = 0.55 (0.46) m=0

70-30 Brass

2

n = 0.36 (0.22) m = -0.01

n=0.23

m = 0.012 AKDQ Steel

5182-0 Alum

3

n=0.16 m = 0.005

HSLA Steel

n=0.05 m=0.06

4

5

Zn-Ti Alloy

0 25 50 Engineering Strain, %

The Science of Forming

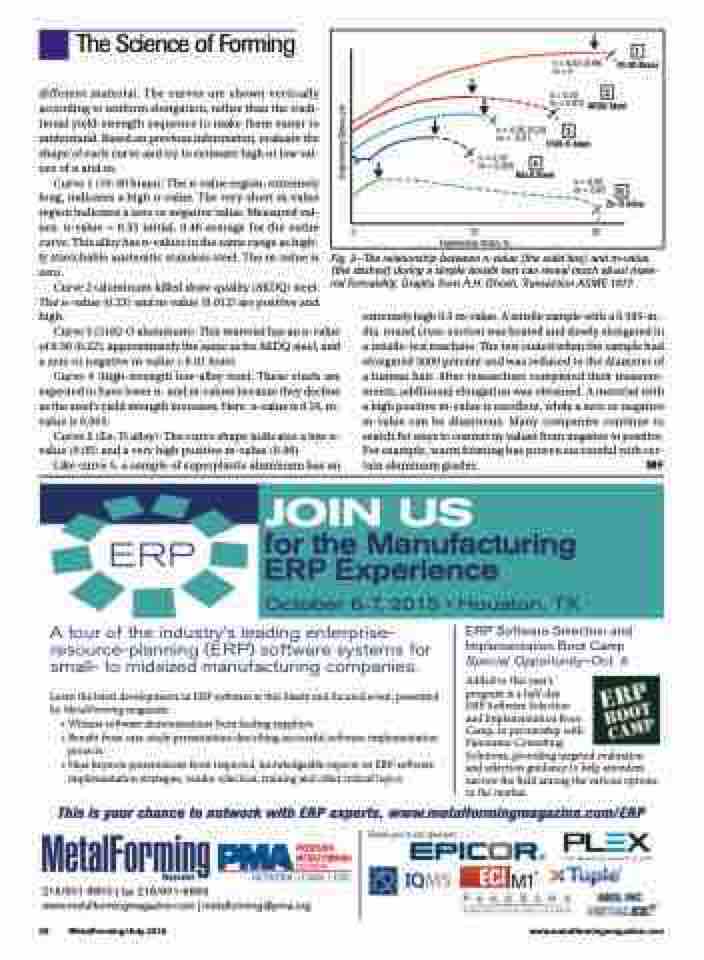

different material. The curves are shown vertically according to uniform elongation, rather than the tradi- tional yield-strength sequence to make them easier to understand. Based on previous information, evaluate the shape of each curve and try to estimate high or low val- ues of n and m.

Curve 1 (70-30 brass): The n-value region, extremely long, indicates a high n-value. The very-short m-value region indicates a zero or negative value. Measured val- ues: n-value = 0.55 initial, 0.46 average for the entire curve. This alloy has n-values in the same range as high- ly stretchable austenitic stainless steel. The m-value is zero.

Curve 2 (aluminum-killed draw-quality (AKDQ) steel: The n-value (0.23) and m-value (0.012) are positive and high.

Fig. 3—The relationship between n-value (the solid line) and m-value (the dashed) during a simple tensile test can reveal much about mate- rial formability. Graphs from A.H. Ghosh, Transaction ASME 1977.

Curve 3 (5182-O aluminum): This material has an n-value of 0.36 (0.22), approximately the same as for AKDQ steel, and a zero or negative m-value (-0.01 here).

Curve 4 (high-strength low-alloy steel: These steels are expected to have lower n- and m-values because they decline as the steel’s yield strength increases. Here, n-value is 0.16, m- value is 0.005.

Curve 5 (Zn-Ti alloy): The curve shape indicates a low n- value (0.05) and a very high positive m-value (0.06).

Like curve 5, a sample of superplastic aluminum has an

extremely high 0.5 m-value. A tensile sample with a 0.505-in.- dia. round cross-section was heated and slowly elongated in a tensile-test machine. The test ended when the sample had elongated 3000 percent and was reduced to the diameter of a human hair. After researchers completed their measure- ments, additional elongation was obtained. A material with a high positive m-value is excellent, while a zero or negative m-value can be disastrous. Many companies continue to search for ways to convert m-values from negative to positive. For example, warm forming has proven successful with cer- tain aluminum grades. MF

JOIN US

for the Manufacturing ERP Experience

October 6-7, 2015 • Houston, TX

A tour of the industry’s leading enterprise- resource-planning (ERP) software systems for small- to midsized manufacturing companies.

Learn the latest developments in ERP software at this timely and focused event, presented by MetalForming magazine.

• Witness software demonstrations from leading suppliers.

• Benefit from case-study presentations describing successful software-implementation

projects.

• Hear keynote presentations from respected, knowledgeable experts on ERP-software

implementation strategies, vendor selection, training and other critical topics.

ERP Software Selection and Implementation Boot Camp Special Opportunity—Oct. 8

Added to this year’s

program is a half-day

ERP Software Selection

and Implementation Boot

Camp, in partnership with

Panorama Consulting

Solutions, providing targeted evaluation and selection guidance to help attendees narrow the field among the various options in the market.

This is your chance to network with ERP experts, www.metalformingmagazine.com/ERP

Thank you to our sponsors:

216/901-8800 | fax 216/901-9669 www.metalformingmagazine.com | metalforming@pma.org

38 MetalForming/July 2015

www.metalformingmagazine.com

Engineering Stress, psi