Page 57 - MetalForming May 2015

P. 57

Fig. 3—Distribution of deformation depends strongly on the n-values shown in the center of the graphs. The dashed line indi- cates the direction for higher-strength steels with n-values less than 0.20.

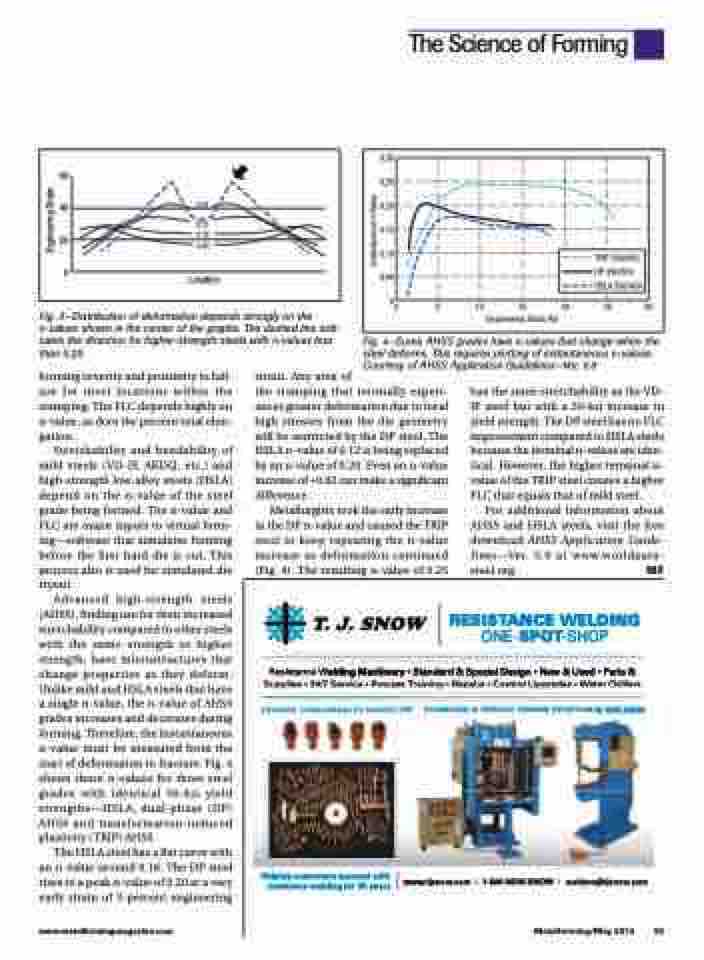

Fig. 4—Some AHSS grades have n-values that change when the steel deforms. This requires plotting of instantaneous n-values. Courtesy of AHSS Application Guidelines—Ver. 5.0

forming severity and proximity to fail- ure for most locations within the stamping. The FLC depends highly on n-value, as does the percent total elon- gation.

Stretchability and bendability of mild steels ( VD-IF, AKDQ, etc.) and high-strength low-alloy steels (HSLA) depend on the n-value of the steel grade being formed. The n-value and FLC are major inputs to virtual form- ing—software that simulates forming before the first hard die is cut. This process also is used for simulated die tryout.

Advanced high-strength steels (AHSS), finding use for their increased stretchability compared to other steels with the same strength or higher strength, have microstructures that change properties as they deform. Unlike mild and HSLA steels that have a single n-value, the n-value of AHSS grades increases and decreases during forming. Therefore, the instantaneous n-value must be measured from the start of deformation to fracture. Fig. 4 shows these n-values for three steel grades with identical 50-ksi yield strengths—HSLA, dual-phase (DP) AHSS and transformation-induced plasticity (TRIP) AHSS.

The HSLA steel has a flat curve with an n-value around 0.16. The DP steel rises to a peak n-value of 0.20 at a very early strain of 3-percent engineering

strain. Any area of

the stamping that normally experi- ences greater deformation due to local high stresses from the die geometry will be restricted by the DP steel. The HSLA n-value of 0.12 is being replaced by an n-value of 0.20. Even an n-value increase of +0.02 can make a significant difference.

Metallurgists took the early increase in the DP n-value and caused the TRIP steel to keep repeating the n-value increase as deformation continued (Fig. 4). The resulting n-value of 0.25

has the same stretchability as the VD- IF steel but with a 30-ksi increase in yield strength. The DP steel has no FLC improvement compared to HSLA steels because the terminal n-values are iden- tical. However, the higher terminal n- value of the TRIP steel creates a higher FLC that equals that of mild steel.

For additional information about AHSS and HSLA steels, visit the free download AHSS Application Guide- lines—Ver. 5.0 at www.worldauto- steel.org. MF

RESISTANCE WELDING ONE-SPOT-SHOP

The Science of Forming

60 40 20

0

0.20

0.25 0.35 0.45

Location

0.30 0.25 0.20 0.15 0.10 0.05

0

0 5 10 15 20 25 30 Engineering Strain (%)

TRI

P 350/600

DP 350/600 HSLA 350/450

l

Supplies • 24/7 Service • Process Training • Repairs • Control Upgrades • Water Chillers

Resistance Welding Machinery

y

y•

•

• S

S

St

t

ta

a

a

nd

da

a

ar

rd

d & S

S

p

p

e

e

e

ec

c

c

ial

l

l

D

D

D

De

es

s

s

si

i

i

ign

n

n

n•

•

N

N

Ne

e

w

w

w & Used

d

• P

Part

ts &

&

DIVERSE CONSUMABLES INVENTORY

STANDARD & SPECIAL DESIGN RESISTANCE WELDERS

www.metalformingmagazine.com

MetalForming/May 2015 55

Helpingcustomerssucceedwith resistance welding for 50 years

www.tjsnow.com | 1-800-NOW-SNOW | welders@tjsnow.com

Engineering Strain

Instantaneous n-Value