Page 44 - MetalForming May 2015

P. 44

What’s New in

Die Design

and Simulation

Software

BY LOUIS A. KREN, SENIOR EDITOR

With MetalForming magazine’s Die Design and Simulation Software Experience set for May 27-28, in Troy, MI, it is a good time to get up to speed on recent develop- ments in this technology. Read on for some updates.

Support Early On in Product Design

New in 2015 from Engineering Tech- nology Associates, Inc. (ETA) (www.eta.com), Troy, MI, Dynaform’s D-Eval Module was created especially to support and analyze CAD-based tooling and engineering designs. D- Eval is tailored to support engineers in the early stages of the product- design cycle, allowing them to take manufacturability into consideration ahead of the tooling stage. The CAE tools contained in D-Eval provide “What If” studies on tipping adjust- ments; binder generation and modifi- cations; morphing; drawbead layout; line-bead and geometry-bead conver- sion; addendum modifications; and die-design modifications. The module also enables CAM trim evaluation and trim-line checks.

D-Eval includes the IncSolver, devel- oped solely for simulating sheetmetal- forming processes and enabling gen-

eration of reliable forma- bility results in a reason- able timeframe, according to ETA officials.

Using shared-memory processing, users can take advantage of the multiple CPUs, multiple cores and multiple threads of the lat- est Windows computing platform, reportedly allow- ing for rapid and reliable results. In most cases with a four-core CPU, formabili- ty results reportedly can be generated within minutes.

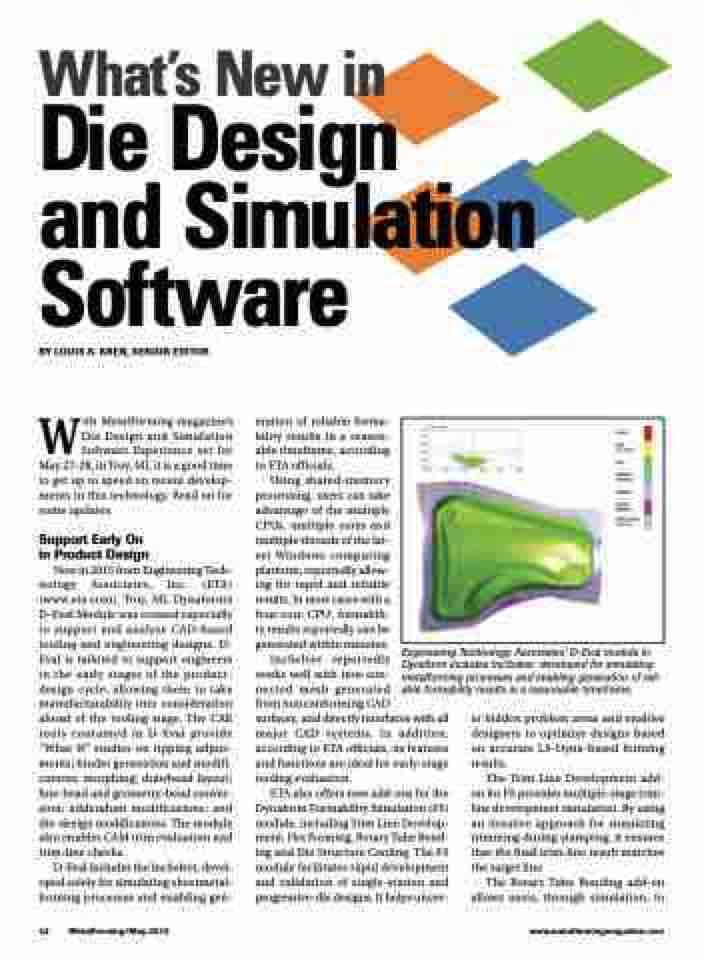

Engineering Technology Associates’ D-Eval module in Dynaform includes IncSolver, developed for simulating metalforming processes and enabling generation of reli- able formability results in a reasonable timeframe.

42 MetalForming/May 2015

www.metalformingmagazine.com

IncSolver reportedly

works well with non-con-

nected mesh generated

from nonconforming CAD

surfaces, and directly interfaces with all major CAD systems. In addition, according to ETA officials, its features and functions are ideal for early-stage tooling evaluation.

er hidden problem areas and enables designers to optimize designs based on accurate LS-Dyna-based forming results.

The Trim Line Development add- on for FS provides multiple-stage trim- line development simulation. By using an iterative approach for simulating trimming during stamping, it ensures that the final trim-line result matches the target line.

The Rotary Tube Bending add-on allows users, through simulation, to

ETA also offers new add-ons for the Dynaform Formability Simulation (FS) module, including Trim Line Develop- ment, Hot Forming, Rotary Tube Bend- ing and Die Structure Cooling. The FS module facilitates rapid development and validation of single-station and progressive-die designs. It helps uncov-