Page 41 - MetalForming May 2015

P. 41

Short/ Spray

Spray

Pulse

Modified A

Pulsed Spray* B

Wire-feed speed, in./min.

245

300

245

263/307

263/307

Volts

15.5 (synergic)

21.5 (synergic)

23.7 (synergic)

24.2/26.7

24.2/26.7

Duration

N/A

N/A

N/A

0.35 sec./0.10 sec.

0.75 sec./0.20 sec.

Amps (avg.)

162

212

172

173

188

Travel Speed, in./min.

26

36

36

25

25

*Modified pulsed-spray welding performed using Esab’s Aristo SuperPulse pack- age—an AristoMig 4004i Pulse inverter power source and AristoFeed wire-feed unit.

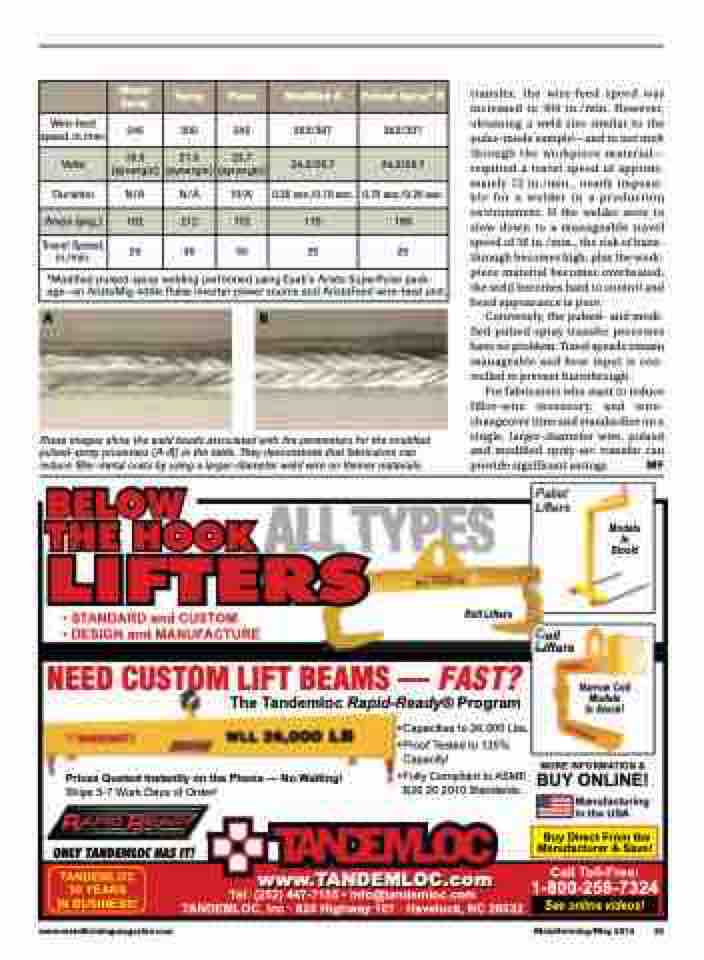

A

These images show the weld beads associated with the parameters for the modified pulsed-spray processes (A-B) in the table. They demonstrate that fabricators can reduce filler-metal costs by using a larger-diameter weld wire on thinner materials.

transfer, the wire-feed speed was increased to 300 in./min. However, obtaining a weld size similar to the pulse-mode sample—and to not melt through the workpiece material— required a travel speed of approxi- mately 72 in./min., nearly impossi- ble for a welder in a production environment. If the welder were to slow down to a manageable travel speed of 36 in./min., the risk of burn- through becomes high, plus the work- piece material becomes overheated, the weld becomes hard to control and bead appearance is poor.

Conversely, the pulsed- and modi- fied pulsed-spray transfer processes have no problem. Travel speeds remain manageable and heat input is con- trolled to prevent burnthrough.

For fabricators who want to reduce filler-wire inventory, and wire- changeover time and standardize on a single, larger-diameter wire, pulsed and modified spray-arc transfer can provide significant savings. MF

THE HOOK

BELOW ALL TYPES

LIFTERS

• STANDARD and CUSTOM

• DESIGN and MANUFACTURE

Roll Lifters

B

Pallet Lifters

Models In Stock!

NEED CUSTOM LIFT BEAMS — FAST? The Tandemloc Rapid-Ready® Program

Coil Lifters

Narrow Coil Models In Stock!

Prices Quoted Instantly on the Phone — No Waiting!

Ships 5-7 Work Days of Order!

ONLY TANDEMLOC HAS IT!

Capacities to 26,000 Lbs.

Proof Tested to 125% Capacity!

Fully Compliant to ASME B30.20 2010 Standards.

MORE INFORMATION &

BUY ONLINE!

Manufacturing in the USA

Buy Direct From the Manufacturer & Save!

TANDEMLOC 30 YEARS IN BUSINESS!

www.TANDEMLOC.com Call Toll-Free: www.TANDEMLOC.com 1-800-258-7324

Tel: (252) 447-7155 • info@tandemloc.com TANDEMLOC, Inc · 824 Highway 101 · Havelock, NC 28532

See online videos!

www.metalformingmagazine.com

MetalForming/May 2015 39