Page 38 - MetalForming March 2015

P. 38

Polymer Wheels

The move to LED lighting in residential and commercial settings, in place of incandescent, not only impacts aesthetics and efficiency but also sheds new light on metal- fabrication practices. For starters, reflectors typically made by hydroforming now are spun; here’s a new spinning tool lighting the way to improved profitability.

BY BRAD F. KUVIN, EDITOR

Down south in Lithia Springs, GA, metalformer and fabricator Reflek Manufacturing calls itself “your partner for a brighter future.” That’s because the company manufac- tures millions of dollars’ worth of alu- minum reflectors every year from its 100,000-sq-ft. facility.

“Back in the day,” says Reflek vice president of sales and marketing Alan Dorsky, “hydroforming was the manu- facturing process of choice for most of the reflectors we made, performed primarily at our headquarters plant in Fall River, MA. That’s because tradi- tional incandescent lighting required more custom-shaped parts, formed from blanks of all sorts of shapes and sizes. Now, due to the trend toward LED lighting in commercial and resi- dential applications, reflectors tend to be circular. That makes metal spinning

Support Aggressive Metal Spinning

36 MetalForming/March 2015

www.metalformingmagazine.com

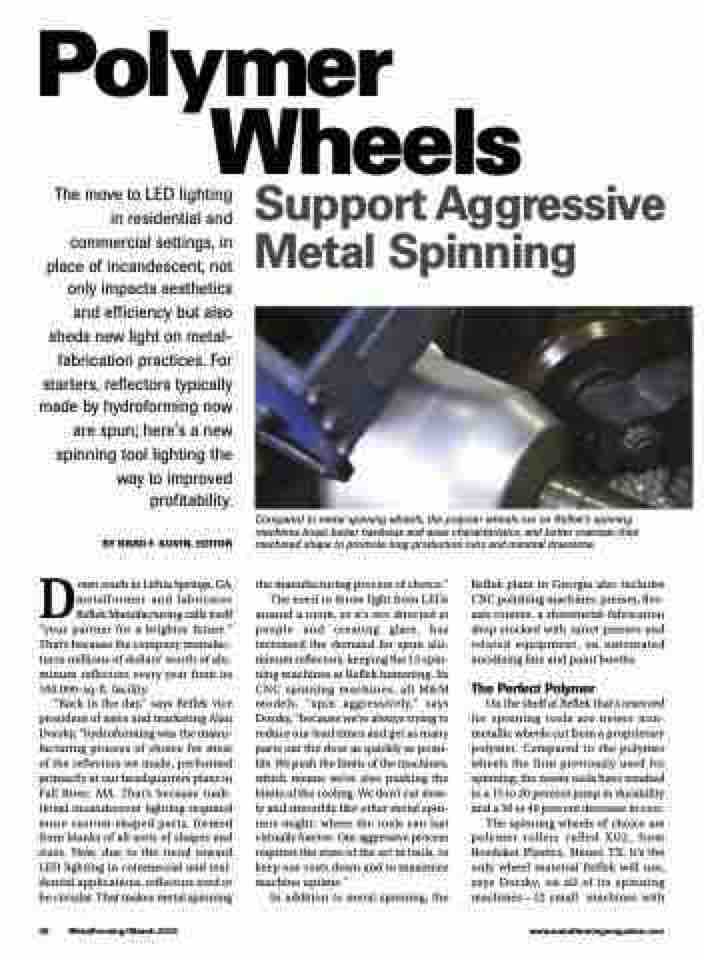

Compared to metal spinning wheels, the polymer wheels run on Reflek’s spinning machines boast better hardness and wear characteristics, and better maintain their machined shape to promote long production runs and minimal downtime.

the manufacturing process of choice.” The need to throw light from LEDs around a room, so it’s not directed at people and creating glare, has increased the demand for spun alu- minum reflectors, keeping the 15 spin- ning machines at Reflek humming. Its CNC spinning machines, all M&M models, “spin aggressively,” says Dorsky, “because we’re always trying to reduce our lead times and get as many parts out the door as quickly as possi- ble. We push the limits of the machines, which means we’re also pushing the limits of the tooling. We don’t cut slow- ly and smoothly like other metal spin- ners might, where the tools can last virtually forever. Our aggressive process requires the state of the art in tools, to keep our costs down and to maximize

machine uptime.”

In addition to metal spinning, the

Reflek plant in Georgia also includes CNC polishing machines, presses, five- axis routers, a sheetmetal-fabrication shop stocked with turret presses and related equipment, an automated anodizing line and paint booths.

The Perfect Polymer

On the shelf at Reflek that’s reserved for spinning tools are newer non- metallic wheels cut from a proprietary polymer. Compared to the polymer wheels the firm previously used for spinning, the newer tools have resulted in a 15 to 20 percent jump in durability and a 30 to 40 percent decrease in cost.

The spinning wheels of choice are polymer rollers called XU2, from Boedeker Plastics, Shiner, TX. It’s the only wheel material Reflek will use, says Dorsky, on all of its spinning machines—12 small machines with