Page 24 - MetalForming March 2015

P. 24

Motion Controllers in Combined Workcells

Maintenance Touchscreen

DVI Cable

Ethernet

Ethernet

Factory LAN

Supervisory PLC

6 “Punch” Motion Axes

EtherCAT

Delta RMC150

Wireless Router

I/O Panels

Furnance Touchscreen

Forming Touchscreen

2 Forming Axes

Switch

Switch

Ethernet

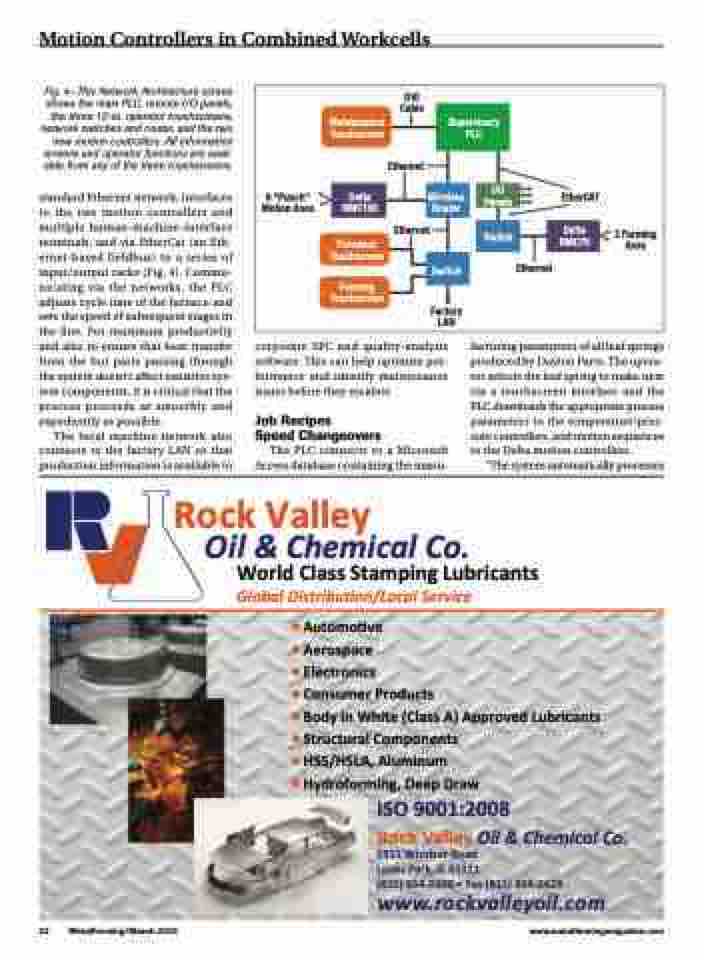

Delta RMC75

Fig. 4—This Network Architecture screen shows the main PLC, remote I/O panels, the three 15-in. operator touchscreens, network switches and router, and the two new motion controllers. All information screens and operator functions are avail- able from any of the three touchscreens.

standard Ethernet network, interfaces to the two motion controllers and multiple human-machine-interface terminals, and via EtherCat (an Eth- ernet-based fieldbus) to a series of input/output racks (Fig. 4). Commu- nicating via the networks, the PLC adjusts cycle time of the furnace and sets the speed of subsequent stages in the line. For maximum productivity and also to ensure that heat transfer from the hot parts passing through the system doesn’t affect sensitive sys- tem components, it is critical that the process proceeds as smoothly and expediently as possible.

The local machine network also connects to the factory LAN so that production information is available to

corporate SPC and quality-analysis software. This can help optimize per- formance and identify maintenance issues before they escalate.

Job Recipes

Speed Changeovers

The PLC connects to a Microsoft Access database containing the manu-

facturing parameters of all leaf springs produced by Dayton Parts. The opera- tor selects the leaf spring to make next via a touchscreen interface and the PLC downloads the appropriate process parameters to the temperature/pres- sure controllers, and motion sequences to the Delta motion controllers.

“The system automatically processes

+",(-%.('//%01'23456%789,4#'51/

.#,/+#$����������������� �������

� ���������

�%:),"/3'#)

�%;()#1,"54#/

�%."5/82),%<,"-8#1/

� ���� �� ����� ������ �� �������� ���������� �%01,8#18,'(%."23"5)51/ �%=00>=07:?%:(824582 �%=*-,"@",2456?%A))3%A,'B

C0D%EFFGHIFFJ

!"#$%&'(()*%!"#$%$&'()"*+#$&,- GEGG%+45-/",%!"'-

����� ����� �� �����

����� �������� � ��� ����� ��������

000-1,*2�+##(3,"#-*,)

!"#$%&'(()*

!"#$%$&'()"*+#$&,-

22 MetalForming/March 2015

www.metalformingmagazine.com