Page 47 - MetalForming January 2015

P. 47

ch

hi

in

ne

er

ry

y•

The Science of Forming

70

60

50

40

30

20

10

0

0 200

500 800

Yield Strength (Mpa)

IF

MI

LD BH

CMn

HSLA

1100 1400 1700

80 70 60 50 40 30 20 10

0 200 500

800 1100 1400 1700 2000 Tensile Strength (MPa)

IF

Mil

d IF- BH

HS

CMn

Austenitic

Stainless (Annealed)

TRIP

HSLA, F-B

DP,CP

M

TWI

S

P

Global Formability Diagram (GFD)

GEN 3 AHSS

MnBF+ HF

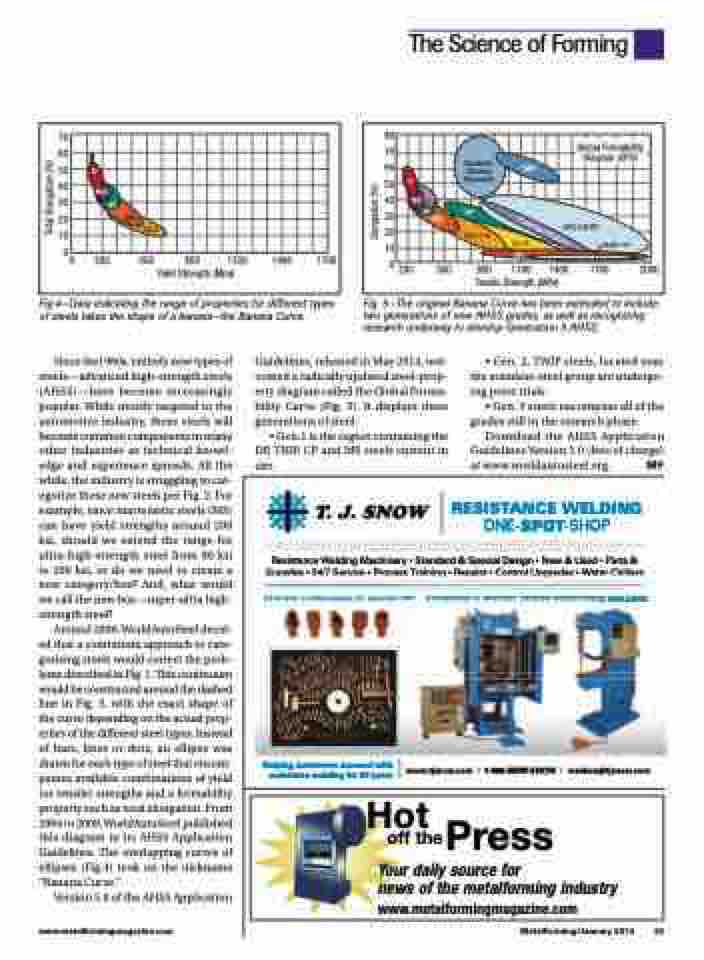

Fig.4—Data indicating the range of properties for different types Fig. 5—The original Banana Curve has been extended to include of steels takes the shape of a banana—the Banana Curve. two generations of new AHSS grades, as well as recognizing

Since the1980s, entirely new types of steels—advanced high-strength steels (AHSS)—have become increasingly popular. While mostly targeted to the automotive industry, these steels will become common components in many other industries as technical knowl- edge and experience spreads. All the while, the industry is struggling to cat- egorize these new steels per Fig. 2. For example, since martensitic steels (MS) can have yield strengths around 200 ksi, should we extend the range for ultra-high-strength steel from 80 ksi to 200 ksi, or do we need to create a new category/box? And, what would we call the new box—super-ultra high- strength steel?

Around 2000, WorldAutoSteel decid- ed that a continuum approach to cate- gorizing steels would correct the prob- lems described in Fig. 1. This continuum would be constructed around the dashed line in Fig. 3, with the exact shape of the curve depending on the actual prop- erties of the different steel types. Instead of bars, lines or dots, an ellipse was drawn for each type of steel that encom- passes available combinations of yield (or tensile) strengths and a formability property such as total elongation. From 2004 to 2009, WorldAutoSteel published this diagram in its AHSS Application Guidelines. The overlapping curves of ellipses (Fig.4) took on the nickname “Banana Curve.”

Version 5.0 of the AHSS Application

Guidelines, released in May 2014, wel- comed a radically updated steel-prop- erty diagram called the Global Forma- bility Curve (Fig. 5). It displays three generations of steel:

• Gen.1 is the region containing the DP, TRIP, CP and MS steels current in use.

• Gen. 2, TWIP steels, located near the stainless-steel group are undergo- ing press trials.

• Gen. 3 steels encompass all of the grades still in the research phase.

Download the AHSS Application Guidelines Version 5.0 (free of charge) at www.worldautosteel.org. MF

RESISTANCE WELDING ONE-SPOT-SHOP

research underway to develop Generation 3 AHSS.

& Supplies • 24/7 Service • Process Training • Repairs • Control Upgrades • Water Chillers

Resistance Welding M

Ma

ac

•S

St

ta

an

nd

da

ar

rd

d&

&S

Sp

pe

ec

ci

ia

al

lD

De

es

s

si

ig

gn

n •

• N

Ne

ew

w &

& U

Us

se

ed

d •

• P

Pa

ar

rt

ts

s &

DIVERSE CONSUMABLES INVENTORY

STANDARD & SPECIAL DESIGN RESISTANCE WELDERS

off the

Hot Press

Your daily source for

news of the metalforming industry www.metalformingmagazine.com

www.metalformingmagazine.com

MetalForming/January 2015 45

Helping customers succeed with resistance welding for 50 years

www.tjsnow.com | 1-800-NOW-SNOW | welders@tjsnow.com

Current Gen 3 Products

Total Elongation (%)

Elongation (%)