Page 20 - MetalForming September 2014

P. 20

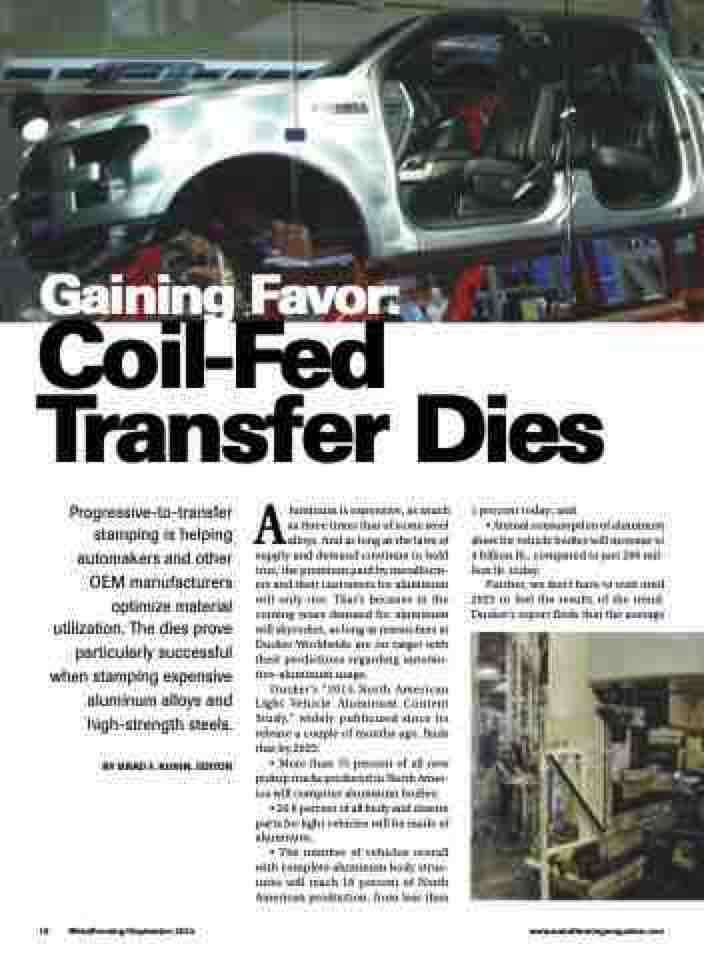

Gaining Favor:

Coil-Fed Transfer Dies

18

MetalForming/September 2014

www.metalformingmagazine.com

Progressive-to-transfer stamping is helping automakers and other OEM manufacturers optimize material utilization. The dies prove particularly successful when stamping expensive aluminum alloys and high-strength steels.

BY BRAD F. KUVIN, EDITOR

Aluminum is expensive, as much as three times that of some steel alloys. And as long as the laws of supply and demand continue to hold true, the premium paid by metalform- ers and their customers for aluminum will only rise. That’s because in the coming years demand for aluminum will skyrocket, as long as researchers at Ducker Worldwide are on target with their predictions regarding automo- tive-aluminum usage.

Ducker’s “2015 North American Light Vehicle Aluminum Content Study,” widely publicized since its release a couple of months ago, finds that by 2025:

• More than 75 percent of all new pickup trucks produced in North Amer- ica will comprise aluminum bodies;

• 26.6 percent of all body and closure parts for light vehicles will be made of aluminum;

• The number of vehicles overall with complete aluminum body struc- tures will reach 18 percent of North American production, from less than

1 percent today; and

• Annual consumption of aluminum

sheet for vehicle bodies will increase to 4 billion lb., compared to just 200 mil- lion lb. today.

Further, we don’t have to wait until 2025 to feel the results of the trend. Ducker’s report finds that the average