Page 22 - MetalForming April 2014

P. 22

Better Software

Begets Engineering Capacity

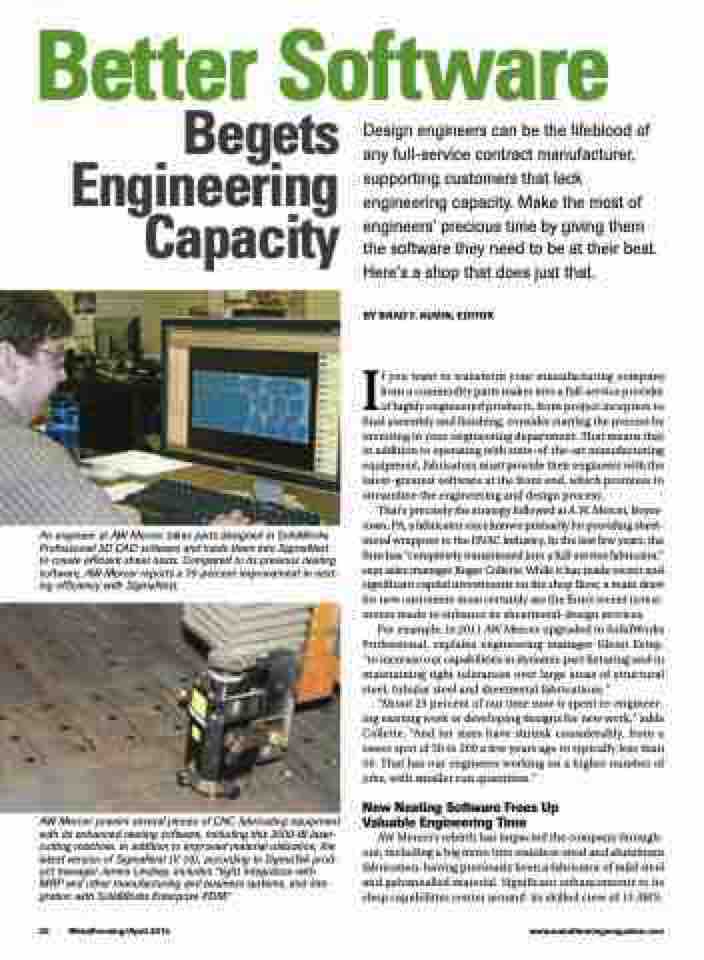

An engineer at AW Mercer takes parts designed in SolidWorks Professional 3D CAD software and loads them into SigmaNest to create efficient sheet nests. Compared to its previous nesting software, AW Mercer reports a 70-percent improvement in nest- ing efficiency with SigmaNest.

Design engineers can be the lifeblood of any full-service contract manufacturer, supporting customers that lack engineering capacity. Make the most of engineers’ precious time by giving them the software they need to be at their best. Here’s a shop that does just that.

BY BRAD F. KUVIN, EDITOR

If you want to transform your manufacturing company from a commodity parts maker into a full-service provider of highly engineered products, from project inception to final assembly and finishing, consider starting the process by investing in your engineering department. That means that in addition to operating with state-of-the-art manufacturing equipment, fabricators must provide their engineers with the latest-greatest software at the front end, which promises to streamline the engineering and design process.

That’s precisely the strategy followed at A.W. Mercer, Boyer- town, PA, a fabricator once known primarily for providing sheet- metal wrappers to the HVAC industry, In the last few years, the firm has “completely transitioned into a full-service fabricator,” says sales manager Roger Collette. While it has made recent and significant capital investments on the shop floor, a main draw for new customers most certainly are the firm’s recent invest- ments made to enhance its sheetmetal-design services.

For example, in 2011 AW Mercer upgraded to SolidWorks Professional, explains engineering manager Glenn Estep, “to increase our capabilities in dynamic part fixturing and in maintaining tight tolerances over large areas of structural steel, tubular steel and sheetmetal fabrications.”

“About 25 percent of our time now is spent re-engineer- ing existing work or developing designs for new work,” adds Collette. “And lot sizes have shrunk considerably, from a sweet spot of 50 to 200 a few years ago to typically less than 50. That has our engineers working on a higher number of jobs, with smaller run quantities.”

New Nesting Software Frees Up Valuable Engineering Time

AW Mercer’s rebirth has impacted the company through- out, including a big move into stainless-steel and aluminum fabrication, having previously been a fabricator of mild steel and galvanealled material. Significant enhancements to its shop capabilities center around its skilled crew of 13 AWS-

AW Mercer powers several pieces of CNC fabricating equipment with its enhanced nesting software, including this 3500-W laser- cutting machine. In addition to improved material utilization, the latest version of SigmaNest (V 10), according to SigmaTek prod- uct manager James Lindsey, includes “tight integration with MRP and other manufacturing and business systems, and inte- gration with SolidWorks Enterprise PDM.”

20 MetalForming/April 2014

www.metalformingmagazine.com