Page 18 - MetalForming April 2014

P. 18

Software for Manufacturing

Shape Nesting for Tube and Pipe Cutting

SigmaTek Systems, LLC, Cincinnati, OH, offers SigmaTube cutting software that supports the processing of round, square, rectangular or triangular tube and pipe, as well as structural materials such as I- and H-beams, C-channel and angle iron. Custom programs are available to fully maximize the advanced features of laser-cutting machines from Mazak, Trumpf, BLM,

Bystronic, Amada and others.

The software operates seamlessly with-

in the SolidWorks environment. Says SigmaTEK product man-

ager James Lindsey:

“Efficient nesting is achieved by

calculating the best possible combinations based on actual geometry, while common- line cutting cuts shared edges at the same time, reducing time and pierce points.” SigmaTek Systems: 513/674-0005; www.sigmanest.com

Cost-Estimating Software Integrates Directly with JobBoss

Costimator cost-estimating software from MTI Systems, Inc., West Springfield, MA, after a recent upgrade to version 12, now integrates with the latest version of Job- Boss, from Exact Software. Costimator exports critical data including cycle times, labor

costs and material usage directly into Job- Boss to help customers quote jobs with a higher degree of accuracy. Also, with the two programs combined, users avoid much of the duplicate data-entry chores during cost estimating.

MTI also reports that its recent Cos- timator customer, machine shop Alpa Pre- cision, L.L.P., Houston, TX, has applied the software to automate what had been a manual estimating process. The software helps the firm identify lower-cost processes and procedures for manufacturing parts, says company owner and president Alber- to Lozano, and it helps deliver more of the information that customers want.

“Costimator reduces my quoting time by more than 20 percent,” says Lozano. “This provides more time to estimate more quotes and for double-checking quotes, as well as offering more pro- gramming time for manufacturing parts.” MTI Systems, Inc.: 800/644-4318; www.mtisystems.com

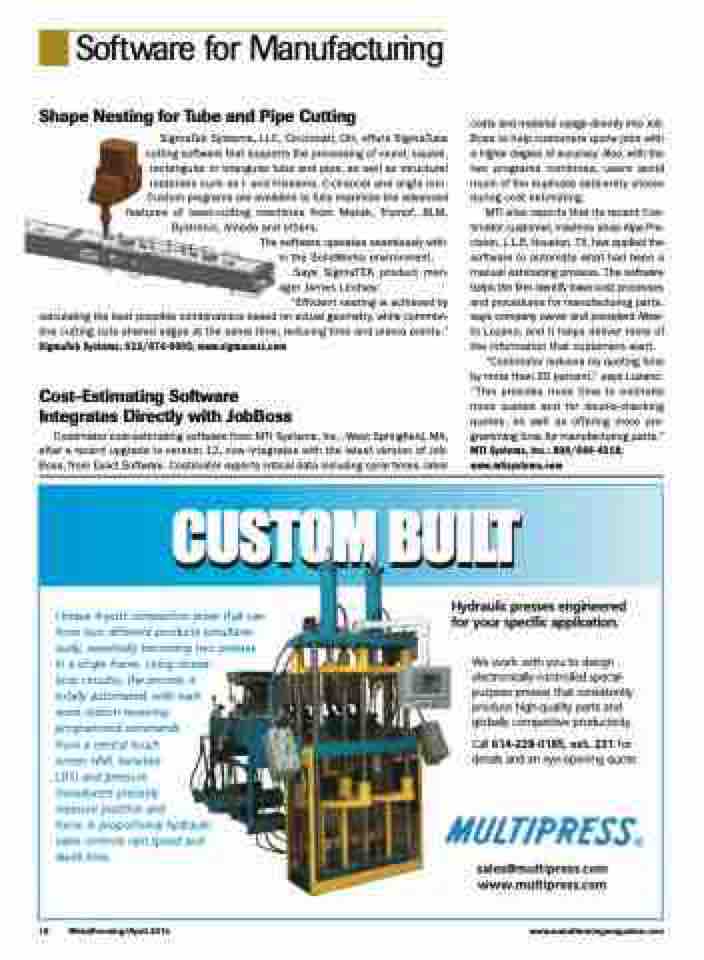

CUSTOM BUILT

CUSTOM BUILT

Unique 4-post compaction press that can form two different products simultane- ously, essentially becoming two presses in a single frame. Using closed-

loop circuitry, the process is totally automated, with each work station receiving programmed commands from a central touch

screen HMI. Sensitive

LDTs and pressure

transducers precisely

measure position and

force. A proportional hydraulic valve controls ram speed and dwell time.

Hydraulic presses engineered for your specific application.

We work with you to design electronically-controlled special- purpose presses that consistently produce high-quality parts and globally competitive productivity.

Call 614-228-0185, ext. 231 for details and an eye-opening quote.

sales@multipress.com www.multipress.com

16 MetalForming/April 2014

www.metalformingmagazine.com