Page 31 - MetalForming November 2013

P. 31

Backup-Roller Support: Backup-roller support is vital to ensure the effectiveness of the backup rollers and prevent work-roll deflection when running AHSS. Backup-roller face width and the cross-section of the support structure are critical to providing proper work-roll support. Simply adding screw jacks to narrow cross bars will not provide the backup-roller support required to achieve a good result.

Journal Support: As mentioned, outboard support of the drive-gear journals is critical to providing the rigidity necessary to withstand the higher horsepower and torque requirements and improve the system gear ratings.

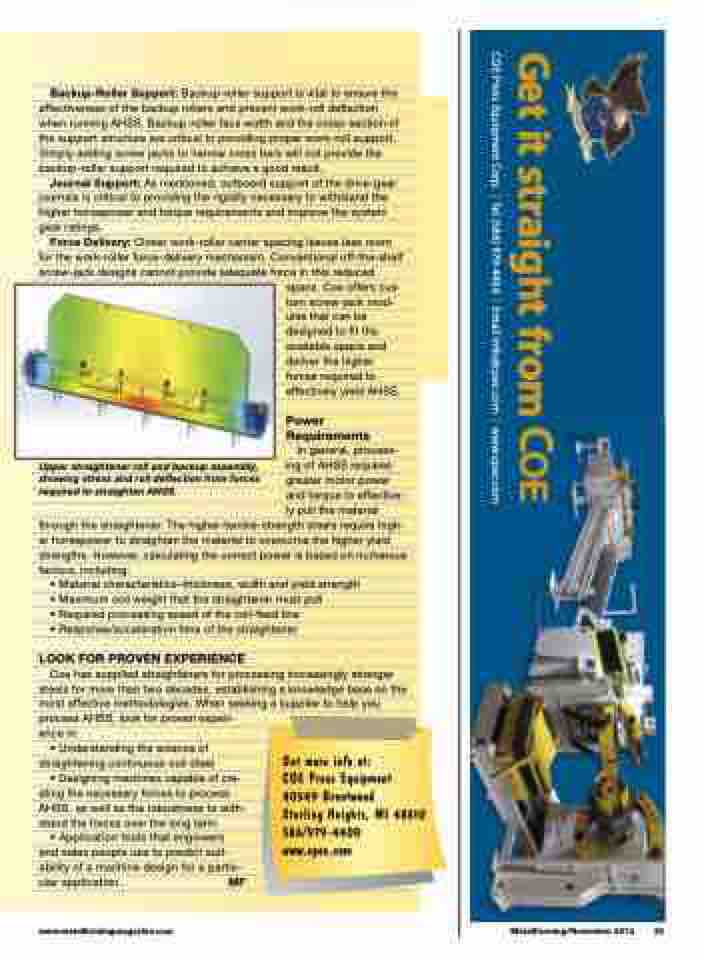

Force Delivery: Closer work-roller center spacing leaves less room for the work-roller force-delivery mechanism. Conventional off-the-shelf screw-jack designs cannot provide adequate force in this reduced

Upper straightener roll and backup assembly, showing stress and roll deflection from forces required to straighten AHSS.

space. Coe offers cus- tom screw-jack mod- ules that can be designed to fit the available space and deliver the higher forces required to effectively yield AHSS.

Power Requirements

In general, process- ing of AHSS requires greater motor power and torque to effective- ly pull the material

through the straightener. The higher-tensile-strength steels require high- er horsepower to straighten the material to overcome the higher yield strengths. However, calculating the correct power is based on numerous factors, including:

• Material characteristics–thickness, width and yield strength • Maximum coil weight that the straightener must pull

• Required processing speed of the coil-feed line

• Response/acceleration time of the straightener

LOOK FOR PROVEN EXPERIENCE

Coe has supplied straighteners for processing increasingly stronger steels for more than two decades, establishing a knowledge base on the most effective methodologies. When seeking a supplier to help you process AHSS, look for proven experi-

ence in:

• Understanding the science of straightening continuous-coil steel

• Designing machines capable of cre- ating the necessary forces to process AHSS, as well as the robustness to with- stand the forces over the long term

• Application tools that engineers and sales people use to predict suit- ability of a machine design for a partic- ular application. MF

Get more info at:

COE Press Equipment 40549 Brentwood

Sterling Heights, MI 48310 586/979-4400 www.cpec.com

Get it straight from

COE Press Equipment Corp. | Tel (586) 979-4400 | Email info@cpec.com | www.cpec.com

www.metalformingmagazine.com MetalForming/November 2013 29