Page 22 - MetalForming October 2013

P. 22

Servo2

(Servo-Feed Line + Servo Press)

Opens Windows of Opportunities

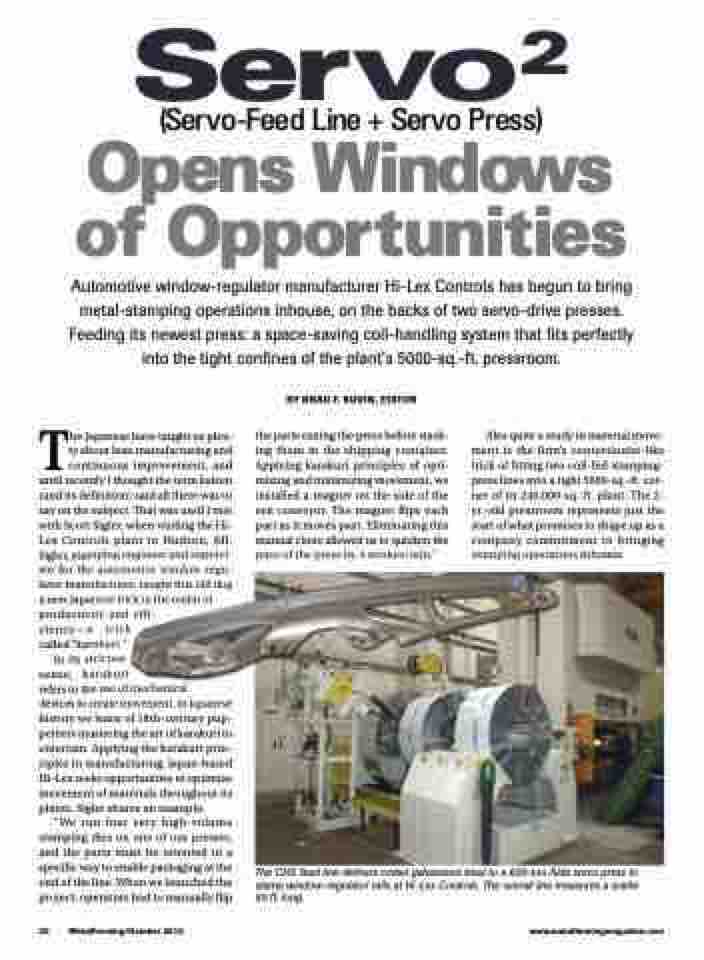

Automotive window-regulator manufacturer Hi-Lex Controls has begun to bring metal-stamping operations inhouse, on the backs of two servo-drive presses. Feeding its newest press: a space-saving coil-handling system that fits perfectly into the tight confines of the plant’s 5000-sq.-ft. pressroom.

The Japanese have taught us plen- ty about lean manufacturing and continuous improvement, and until recently I thought the term kaizen (and its definition) said all there was to say on the subject. That was until I met with Scott Sigler, when visiting the Hi- Lex Controls plant in Hudson, MI. Sigler, stamping engineer and supervi- sor for the automotive window-regu- lator manufacturer, taught this old dog a new Japanese trick in the realm of productivity and effi-

ciency—a trick

called “karakuri.” In its strictest

sense, karakuri

refers to the use of mechanical

devices to create movement. In Japanese history we learn of 18th-century pup- peteers mastering the art of karakuri to entertain. Applying the karakuri prin- ciples in manufacturing, Japan-based Hi-Lex seeks opportunities to optimize movement of materials throughout its plants. Sigler shares an example:

“We run four very high-volume stamping dies on one of our presses, and the parts must be oriented in a specific way to enable packaging at the end of the line. When we launched the project, operators had to manually flip

BY BRAD F. KUVIN, EDITOR

the parts exiting the press before stack- ing them in the shipping container. Applying karakuri principles of opti- mizing and minimizing movement, we installed a magnet on the side of the exit conveyor. The magnet flips each part as it moves past. Eliminating this manual chore allowed us to quicken the pace of the press by 4 strokes/min.”

Also quite a study in material move- ment is the firm’s contortionist-like trick of fitting two coil-fed stamping- press lines into a tight 5000-sq.-ft. cor- ner of its 240,000-sq.-ft. plant. The 2- yr.-old pressroom represents just the start of what promises to shape up as a company commitment to bringing stamping operations inhouse.

20 MetalForming/October 2013

www.metalformingmagazine.com

The CHS feed line delivers coiled galvanized steel to a 600-ton Aida servo press to stamp window-regulator rails at Hi-Lex Controls. The overall line measures a svelte 50 ft. long.