Page 20 - MetalForming August 2013

P. 20

New Deep- Draw Press

Extinguishes

Productivity

Limiters

...from an aging, outdated press, by featuring the ability to program precise cycle parameters including main ram, knockout cylinder and draw-cushion force and position; create and store proven recipes; and increase energy efficiency and

machine safety.

Meggitt Safety Sys-

tems, Simi Valley, CA, manufactures extreme- environment fire-protection and safety apparatus—fire and overheat detectors and other types of sensors— for aircraft, spacecraft, boats, trains, missiles and other industrial and ener- gy platforms. Over the years, the firm’s product lines have grown, and along with that new-product development has come the need to upgrade its 1963- vintage hydraulic press. On the firm’s new-press wish list:

• The ability to program and achieve precise cycle parameters, including main ram, knockout cylinder and draw- cushion force and position.

• Recipe functionality, to create and store proven recipes and avoid relying excessively on the skill of individual

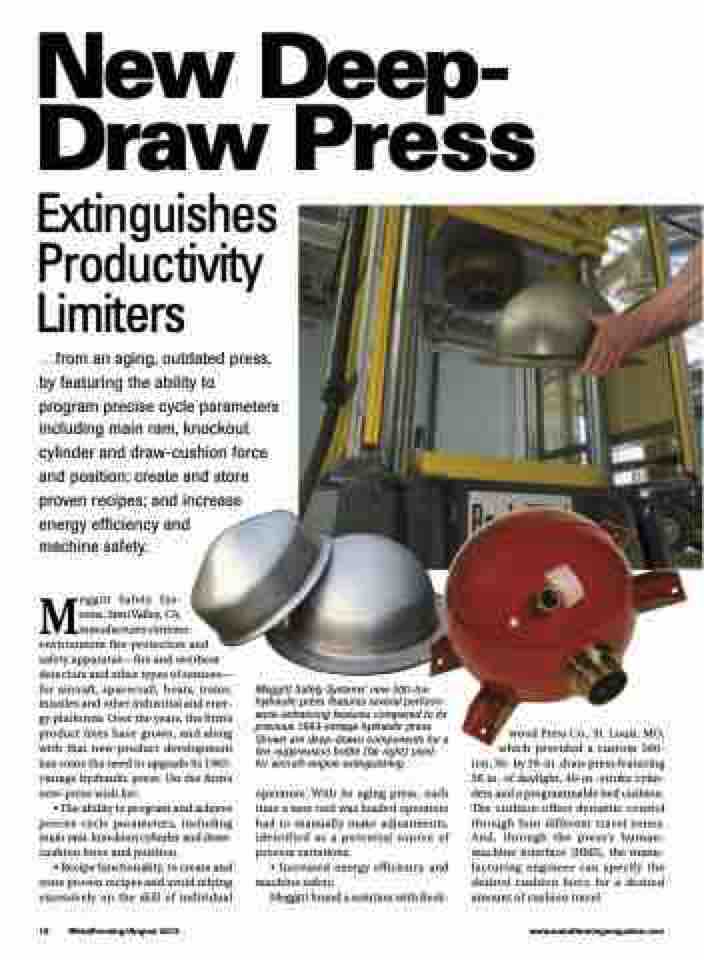

Meggitt Safety Systems’ new 500-ton hydraulic press features several perform- ance-enhancing features compared to its previous 1963-vintage hydraulic press. Shown are deep-drawn components for a fire-suppression bottle (far right) used for aircraft-engine extinguishing.

operators. With its aging press, each time a new tool was loaded operators had to manually make adjustments, identified as a potential source of process variations.

• Increased energy efficiency and machine safety.

Meggitt found a solution with Beck-

wood Press Co., St. Louis, MO, which provided a custom 500- ton, 36- by 36-in. draw press featuring 56 in. of daylight, 40-in.-stroke cylin- ders and a programmable bed cushion. The cushion offers dynamic control through four different travel zones. And, through the press’s human- machine interface (HMI), the manu- facturing engineer can specify the desired cushion force for a desired

amount of cushion travel.

18 MetalForming/August 2013

www.metalformingmagazine.com