Page 24 - MetalForming May 2013

P. 24

down, continuously exposing new cut- ting surfaces—essentially self-sharp- ening. Compared to the grains on more traditional grinding wheels, these fresh cutting points provide a faster cut rate, higher rate of metal removal and longer wheel life, as the grains can be com- pletely utilized through the microfrac- turing process. So, rather than prema- turely expelling rounded or worn aluminum-oxide grains at only a frac- tion of their life, microstructure grains such as ceramic alumina and zirconia alumina work together to cut cooler, allowing the wheel to hold onto the grain longer to extend wheel life.

Choosing the Wheel Well

The key to optimizing performance of an abrasive-grinding and cutting operation is the selection of the best- suited wheel to the particular applica- tion. When selecting the best wheel for the job, consider several factors includ- ing external budgetary rules and the available power sources—low voltage, low air pressure for example—and whether cost reduction and process optimization throughput are the main goals. Many abrasives manufacturers provide grinding solutions geared to meeting specific applications, ranging from rapid stock removal to precision finishing.

There are several different methods

of evaluating the performance of abra- sive wheels. Some wheels are hard-act- ing—they may last a long time but not remove much material. Other wheels are soft-acting—they cut quickly but do not last very long.

To attain the true value of a wheel, combine its cutting action and wheel life. A high-performance wheel pro- vides a very good cut rate and wheel life for the highest total metal removed over the life of the wheel. Measuring and tracking these factors can reveal opportunities to reduce the total cost of an operation, solving production bot- tlenecks and reducing total fabrication costs.

Wheel Performance, All-Around

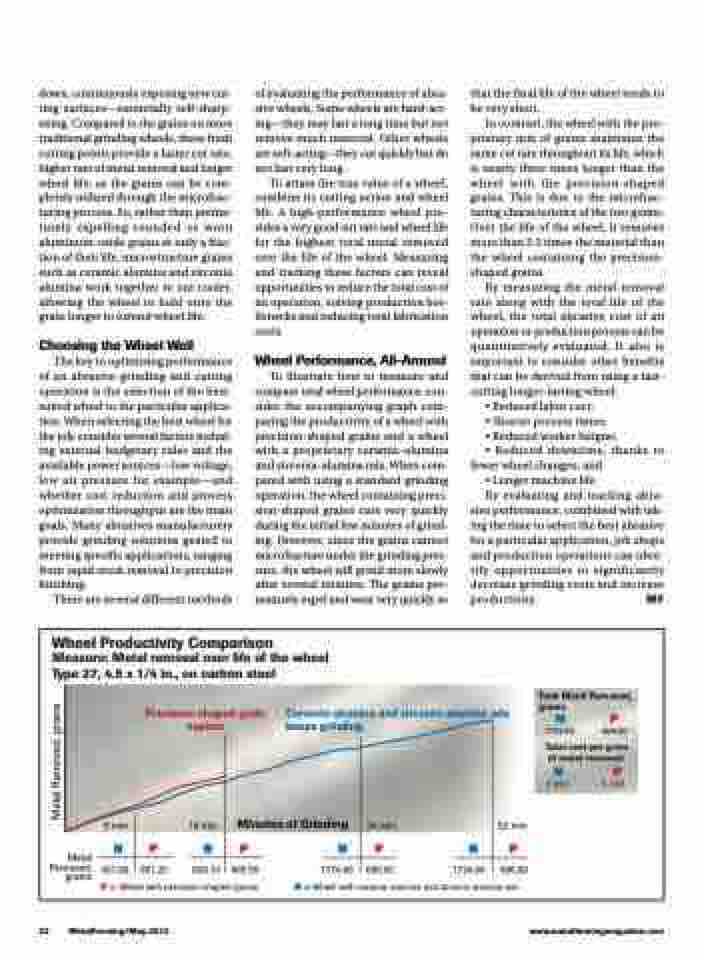

To illustrate how to measure and compare total wheel performance, con- sider the accompanying graph com- paring the productivity of a wheel with precision-shaped grains and a wheel with a proprietary ceramic-alumina and zirconia-alumina mix. When com- pared with using a standard grinding operation, the wheel containing preci- sion-shaped grains cuts very quickly during the initial few minutes of grind- ing. However, since the grains cannot microfracture under the grinding pres- sure, the wheel will grind more slowly after several minutes. The grains pre- maturely expel and wear very quickly so

that the final life of the wheel tends to be very short.

In contrast, the wheel with the pro- prietary mix of grains maintains the same cut rate throughout its life, which is nearly three times longer than the wheel with the precision-shaped grains. This is due to the microfrac- turing characteristics of the two grains. Over the life of the wheel, it removes more than 2.5 times the material than the wheel containing the precision- shaped grains.

By measuring the metal-removal rate along with the total life of the wheel, the total abrasive cost of an operation or production process can be quantitatively evaluated. It also is important to consider other benefits that can be derived from using a fast- cutting longer-lasting wheel:

• Reduced labor cost;

• Shorter process times;

• Reduced worker fatigue;

• Reduced downtime, thanks to

fewer wheel changes; and

• Longer machine life.

By evaluating and tracking abra-

sive performance, combined with tak- ing the time to select the best abrasive for a particular application, job shops and production operations can iden- tify opportunities to significantly decrease grinding costs and increase productivity. MF

Wheel Productivity Comparison Measure: Metal removal over life of the wheel Type 27, 4.5 x 1/4 in., on carbon steel

Precision-shaped grain expires

Ceramic-alumina and zirconia-alumina mix keeps grinding

Total Metal Removed, grams

NP 1724.90 696.50

Total cost per gram of metal removed

NP

Metal grams

$ .001

$ .003

8 min.

16 min.

Minutes of Grinding

34 min.

52 min.

NPNP NP NP Removed, 301.90 361.20 600.10 695.50 1174.80 696.50 1724.90 696.50

P = Wheel with precision-shaped-grains N = Wheel with ceramic alumina and zirconia alumina mix

22 MetalForming/May 2013

www.metalformingmagazine.com

Metal Removed, grams