Page 36 - MetalForming April 2013

P. 36

Four-Roll

Servo Feed

at the High End of theToughness Scale

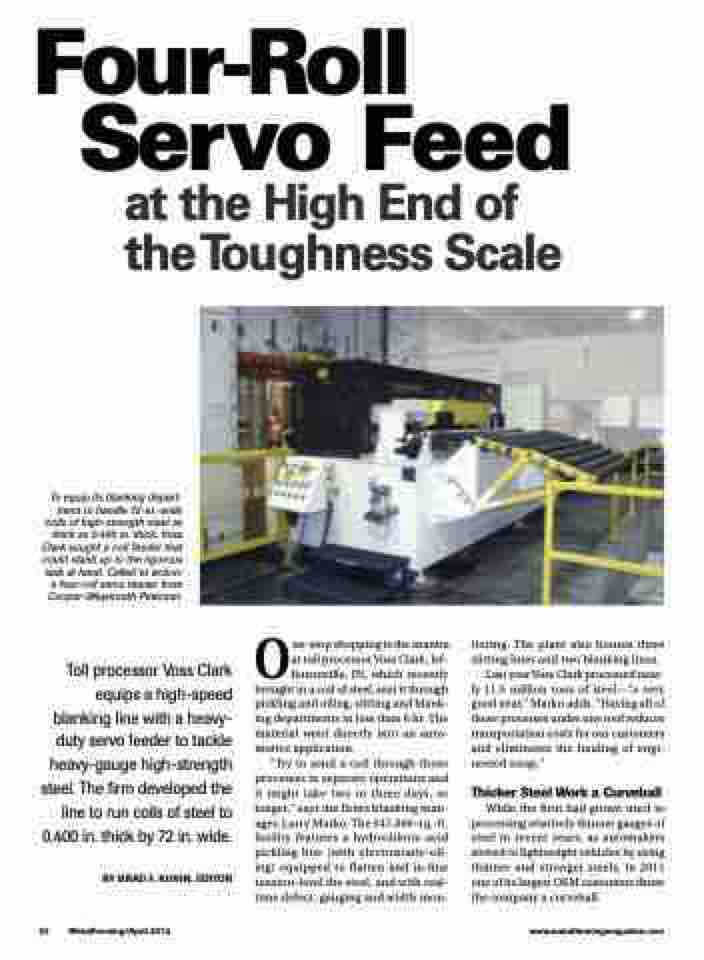

To equip its blanking depart- ment to handle 72-in.-wide coils of high-strength steel as thick as 0.400 in. thick, Voss Clark sought a coil feeder that could stand up to the rigorous task at hand. Called to action: a four-roll servo feeder from Cooper-Weymouth Peterson.

Toll processor Voss Clark equips a high-speed blanking line with a heavy- duty servo feeder to tackle heavy-gauge high-strength steel. The firm developed the line to run coils of steel to 0.400 in. thick by 72 in. wide.

BY BRAD F. KUVIN, EDITOR

One-stop shopping is the mantra at toll processor Voss Clark, Jef- fersonville, IN, which recently brought in a coil of steel, sent it through pickling and oiling, slitting and blank- ing departments in less than 6 hr. The material went directly into an auto- motive application.

“Try to send a coil through those processes in separate operations and it might take two or three days, or longer,” says the firm’s blanking man- ager, Larry Marko. The 547,000-sq.-ft. facility features a hydrochloric-acid pickling line (with electrostatic-oil- ing) equipped to flatten and in-line tension-level the steel, and with real- time defect, gauging and width mon-

itoring. The plant also houses three slitting lines and two blanking lines.

Last year Voss Clark processed near- ly 11.5 million tons of steel—“a very good year,” Marko adds. “Having all of those processes under one roof reduces transportation costs for our customers and eliminates the hauling of engi- neered scrap.”

Thicker Steel Work a Curveball

While the firm had grown used to processing relatively thinner gauges of steel in recent years, as automakers strived to lightweight vehicles by using thinner and stronger steels, in 2011 one of its largest OEM customers threw the company a curveball.

34 MetalForming/April 2013

www.metalformingmagazine.com