Page 41 - MetalForming December 2012

P. 41

a flexible part carrier to allow flexing and movement of the blank without pulling adjacent parts out of position.

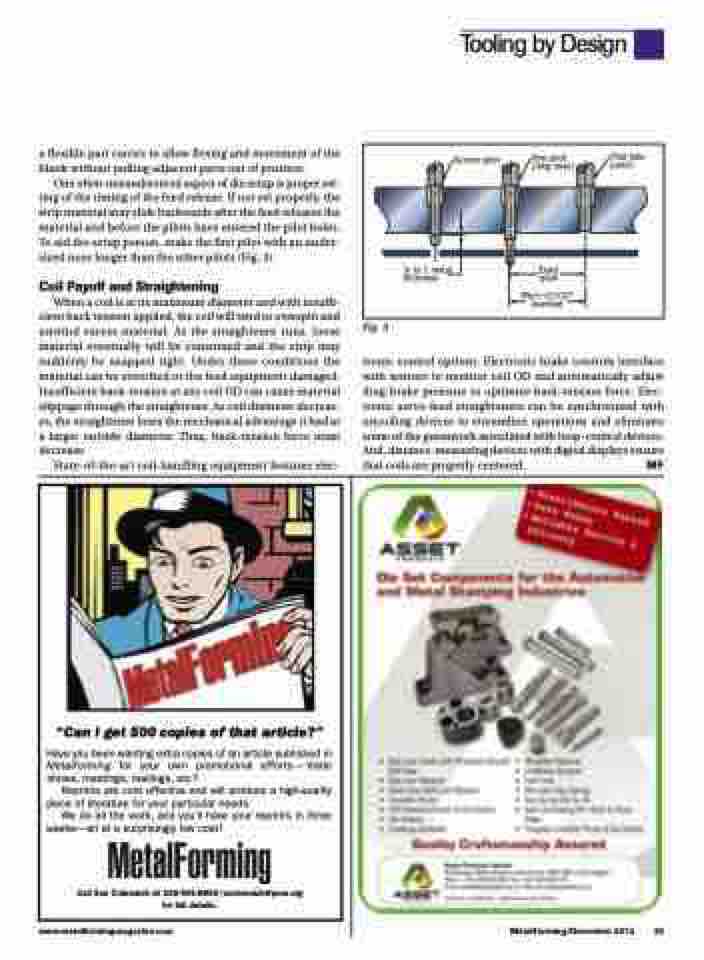

One often-misunderstood aspect of die setup is proper set- ting of the timing of the feed release. If not set properly, the strip material may slide backwards after the feed releases the material and before the pilots have entered the pilot holes. To aid the setup person, make the first pilot with an under- sized nose longer than the other pilots (Fig. 3).

Coil Payoff and Straightening

When a coil is at its maximum diameter and with insuffi- cient back tension applied, the coil will tend to overspin and unwind excess material. As the straightener runs, loose material eventually will be consumed and the strip may suddenly be snapped tight. Under these conditions the material can be stretched or the feed equipment damaged. Insufficient back-tension at any coil OD can cause material slippage through the straightener. As coil diameter decreas- es, the straightener loses the mechanical advantage it had at a larger outside diameter. Thus, back-tension force must decrease.

State-of-the-art coil-handling equipment features elec-

Fig. 3

tronic control options. Electronic brake controls interface with sensors to monitor coil OD and automatically adjust drag-brake pressure to optimize back-tension force. Elec- tronic servo-feed straighteners can be synchronized with uncoiling devices to streamline operations and eliminate some of the guesswork associated with loop-control devices. And, distance-measuring devices with digital displays ensure that coils are properly centered. MF

Tooling by Design

Second pilot

First pilot (long nose)

Exact pitch

Pitch +0.010" overfeed

Pilot hole punch

1⁄2 to 1 metal thickness

“Can I get 500 copies of that article?”

Have you been wanting extra copies of an article published in MetalForming for your own promotional efforts— trade shows, meetings, mailings, etc?

Reprints are cost effective and will produce a high-quality piece of literature for your particular needs.

We do all the work, and you’ll have your reprints in three weeks—all at a surprisingly low cost!

Call Sue Cubranich at 216-901-8800/scubranich@pma.org for full details.

www.metalformingmagazine.com

MetalForming/December 2012 39