Page 11 - MetalForming November 2012

P. 11

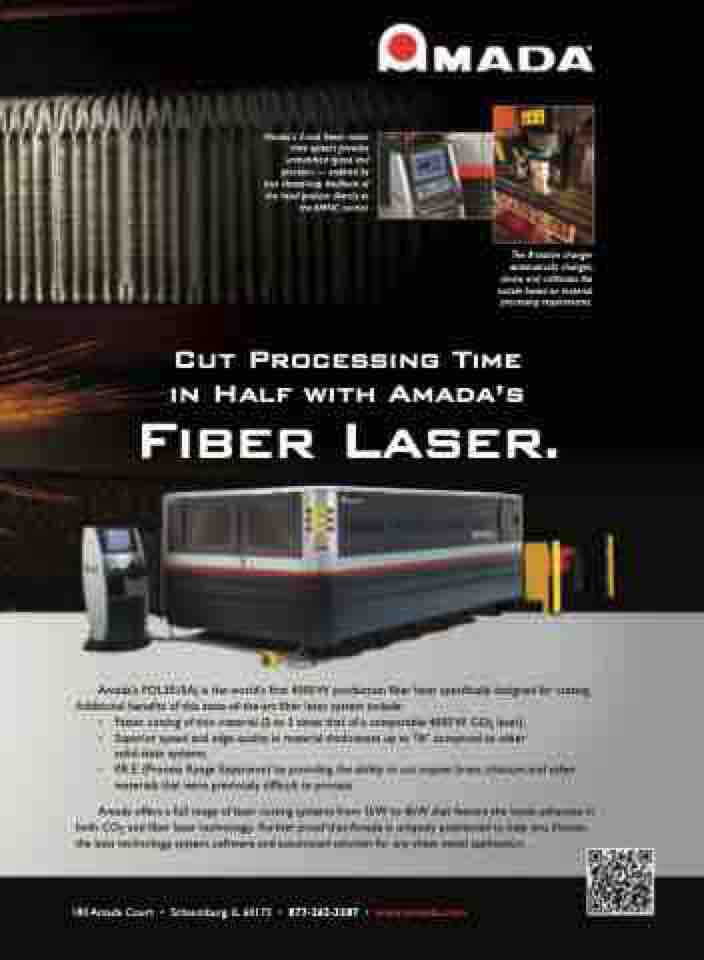

Amada’s 3-axis linear motor drive system provides unmatched speed and precision — enabled by true closed-loop feedback of the head position directly to the AMNC control.

The 8-station changer automatically changes, cleans and calibrates the nozzle based on material processing requirements.

®

Cut Processing Time in Half with Amada’s

Fiber Laser.

Amada’s FOL3015AJ is the world’s first 4000 W production fiber laser specifically designed for cutting. Additional benefits of this state-of-the-art fiber laser system include:

• Faster cutting of thin material (2 to 3 times that of a comparable 4000 W CO2 laser).

• Superior speed and edge quality in material thicknesses up to 7/8˝ compared to other

solid-state systems.

• P.R.E. (Process Range Expansion) by providing the ability to cut copper, brass, titanium and other

materials that were previously difficult to process.

Amada offers a full range of laser cutting systems from 1kW to 6kW that feature the latest advances in both CO2 and fiber laser technology. Further proof that Amada is uniquely positioned to help you choose the best technology, system, software and automated solution for any sheet metal application.

180AmadaCourt • Schaumburg,IL60173 • 877-262-3287 • www.amada.com