Page 19 - MetalForming August 2012

P. 19

core competency,” he says, “we began to take in a lot more work from one of our customers, Textron Marine and Land, requiring us to cut heavy steel plate (2.5 to 3 in. thick) for parts that go into its armored security vehicles (ASVs). We can’t cut that material on our lasers...waterjet is the way to go.”

UHMW Cutting Opens Doors

If 85 percent of its waterjet work is cutting metal alloys, what’s the rest?

“Processing UHMW-PE (ultrahigh molecular-weight polyethylene) parts has become a big part of our waterjet- cutting business,” shares Stimens. Cut- ting UHMW on CNC machines can

prove challeng-

ing, according to

articles on the

subject uncov-

ered on the web-

site of Plastics

Magazine.

“UHMW-PE can

rapidly dull tool

cutting edges,”

says one article,

“causing part

distortion...and attempts to improve poor finishes by filing or sanding will generally result in worsening the appearance.” Thus it would seem waterjet cutting would provide an ideal

Maintenance Tasks

to Keep the Water Flowing

Information provided by Frank Arteaga, head of product marketing, Bystronic Inc.

Fabricators operating waterjet-cutting machines should follow a prescribed set of maintenance tasks, regardless of the machine manufacturer. Let’s first look at the water source, which must be nearly free of heavy metals and minerals that can damage the high-pressure pump. Therefore, most cutting systems include in-line filtration added just prior to the pump inlet. Depending on the quality of the water source, fabricators will need to check these filters weekly or monthly.

Once the water reaches the high-pressure pump, it is pressurized to levels typically above 50,000 PSI. Operating at such a high pressure begs the fabricator to periodically inspect the system’s high-pressure seals and check valves. This typically is recommend- ed at intervals ranging from 300 to 2000 hr., depending on the materials used for the seals and the pressure generated in the pump. Higher pressures will tend to shorten seal and check-valve life; metallic-based seals generally last longer than nonmetallic.

Once the water is pressurized, it is delivered to the cutting head through a high- pressure stainless-steel delivery line. Fabricators should visually inspect this line daily for leaks at connection points. At the end of the delivery line, water will enter the cut- ting head and be focused into a smaller stream of water, typically via a series of reduc- ing components that ends with the water being pushed through a small orifice (0.010- 0.015 in.), typically made from a sapphire or diamond.

As the thin stream of high-pressure water travels through the cutting head’s mixing chamber, abrasive sand (typically garnet) is introduced into the water stream. The water and abrasive then are fired through an abrasive nozzle, typically 0.030- to 0.040-in. dia., used to focus this high-velocity abrasive water stream down to the workpiece. The mix- ing chamber and abrasive nozzle typically experience a shorter replacement interval compared to other system components, due to the erosive nature of the high-pressure water mixed with the abrasive garnet. Typically these components will need to be replaced every 100 hr. or so. Component life will be shorter for those applications using higher pressures or more abrasive grit.

As the abrasive water stream contacts the workpiece, it erodes the material, which then is collected into the catch tank below. There are several ways to remove this waste stream of water, abrasive material and eroded material. In automated setups we find closed-loop recycling systems that filter and recondition the water for reuse in the high-pressure pump. Fabricators also can use separators that will remove the abrasive sludge from the water tank and deposit it into a container where it can either be dis- posed of or separated for further use.

Additional maintenance tasks include greasing mechanical-system components such as motion systems, and performing oil changes on motors and pumps as required by the manufacturer.

www.metalformingmagazine.com

MetalForming/August 2012 17

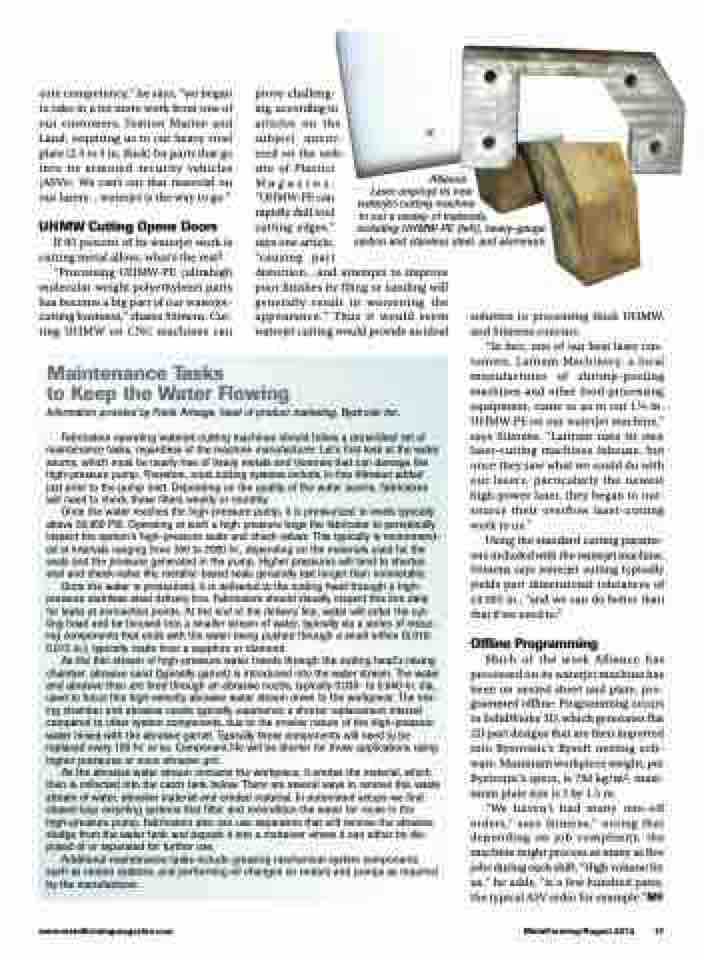

Alliance Laser employs its new waterjet-cutting machine

to cut a variety of materials,

including UHMW-PE (left), heavy-gauge

carbon and stainless steel, and aluminum.

solution to processing thick UHMW, and Stimens concurs.

“In fact, one of our best laser cus- tomers, Laitram Machinery, a local manufacturer of shrimp-peeling machines and other food-processing equipment, came to us to cut 11⁄4-in. UHMW-PE on our waterjet machine,” says Stimens. “Laitram runs its own laser-cutting machines inhouse, but once they saw what we could do with our lasers, particularly the newest high-power laser, they began to out- source their overflow laser-cutting work to us.”

Using the standard cutting parame- ters included with the waterjet machine, Stimens says waterjet cutting typically yields part dimensional tolerances of ±0.005 in., “and we can do better than that if we need to.”

Offline Programming

Much of the work Alliance has processed on its waterjet machine has been on nested sheet and plate, pro- grammed offline. Programming occurs in SolidWorks 3D, which generates flat 2D part designs that are then imported into Bystronic’s Bysoft nesting soft- ware. Maximum workpiece weight, per Bystronic’s specs, is 790 kg/m2; maxi- mum plate size is 3 by 1.5 m.

“We haven’t had many one-off orders,” says Stimens,” noting that depending on job complexity, the machine might process as many as five jobs during each shift. “High volume for us,” he adds, “is a few hundred parts, the typical ASV order for example.”MF